Teardown of Apple iPhone 15's Included USB-C Cable (A2795)

Introduction

The transition to the USB-C port in the iPhone 15 series has brought significant changes to the included cables compared to their predecessors. In fact, the appearance of the cable is strikingly similar to Apple 240W USB-C Charge Cable we recently took apart, both featuring a dual USB-C woven design. So, how does the performance of this new included cable stack up, and what are the differences in build quality between these two cables? Let's find out.

Product Appearance

As usual, it's fixed by cardboard.

Upon closer examination, it closely resembles Apple's retail 60W USB-C Charge Cable (A2795), suggesting that their performance may be similar.

There is no protective sleeve between the connector and the cable.

Surprisingly, its model number is also A2795, indicating it should be identical to the retail version.

It adopts a non full-pin design.

Just like the Apple 240W USB-C Charge Cable, the woven outer layer twists the fibers into strands before arranging and weaving them together, preventing tangling and enhancing durability.

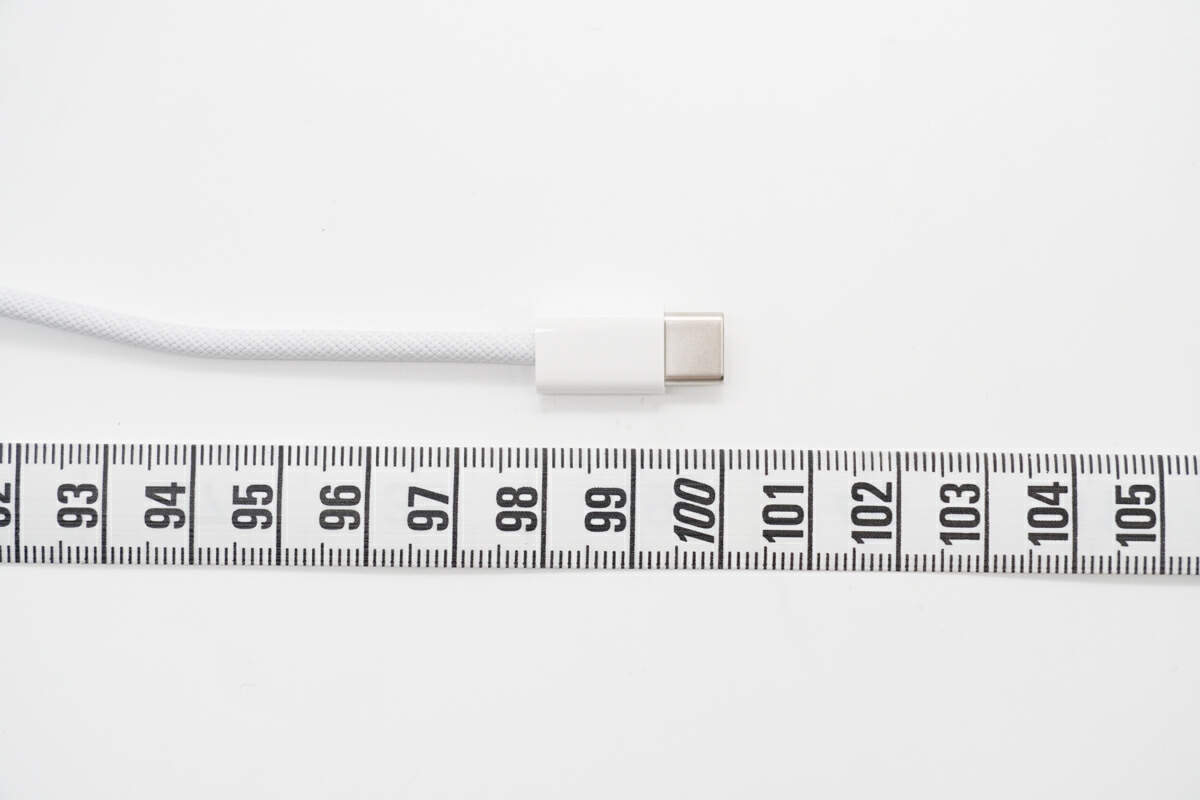

Unlike the previous leak, the cable length is only 1m (3' 3.36'').

And the diameter is about 3.3mm (0.13 inches).

This is how it looks like on my hand.

Compared to the 240W one, the result speaks for itself.

The overall weight is about 19g (0.67 oz).

ChargerLAB POWER-Z KM003C shows it doesn't have an E-marker chip.

Test

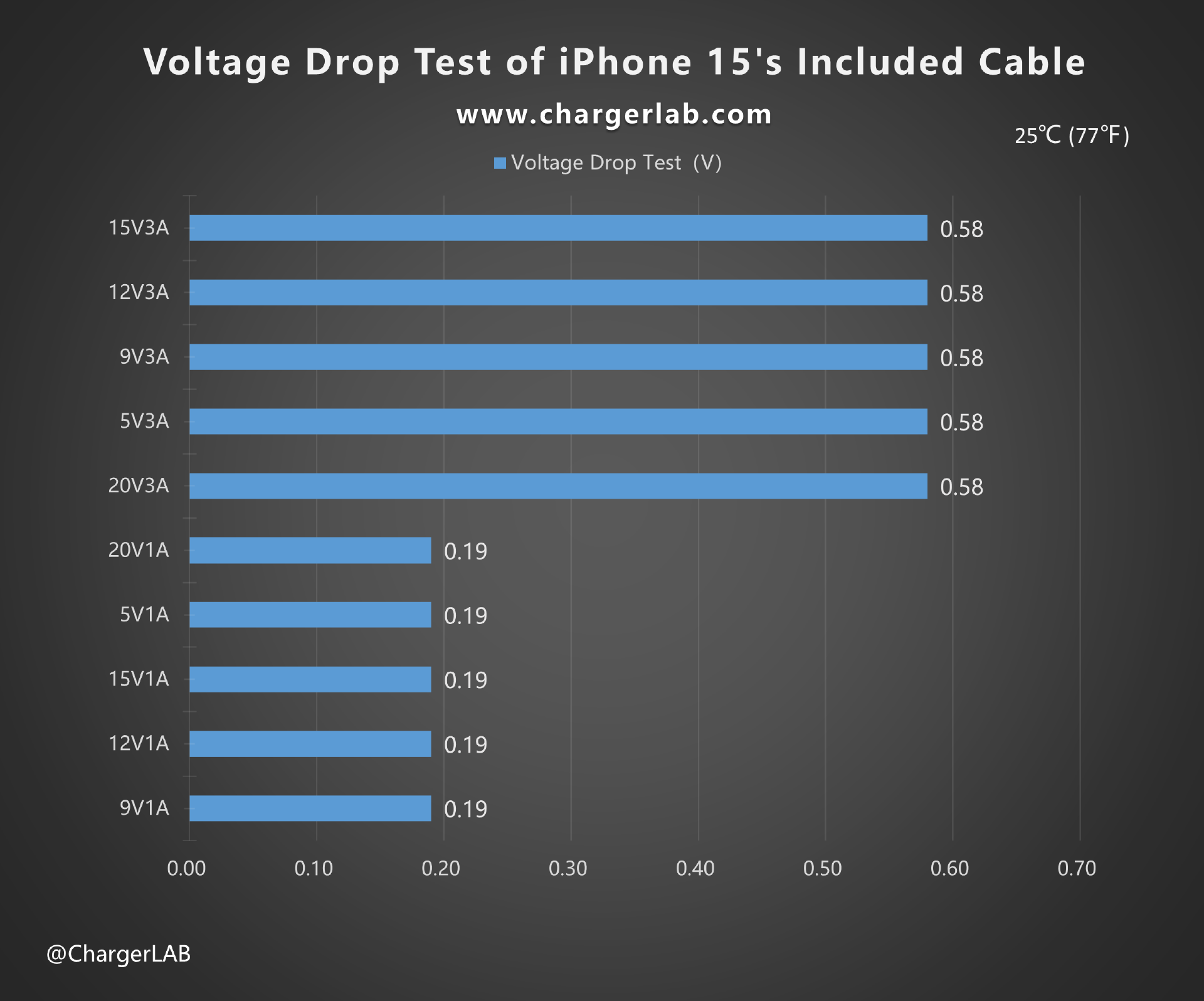

Firstly, we performed a voltage drop test using the brand-new ChargerLAB P240 Bidirectional Multi-protocol Power Supply, which has not yet been released.

This test measured the difference between the input and output voltages, which represents the voltage drop. The results are shown in the bar chart, providing an easy-to-understand visualization.

From the chart, we can see that the voltage drop falls into two categories: 0.19 and 0.58, slightly higher than the 240W version.

Using this cable to charge the 16-inch MacBook Pro. The measured charging power is approximately 58W, so it only supports 20V3A 60W.

Lastly, we connected this cable to a laptop and an SSD enclosure. The Disk Speed Test shows the reading and writing speed can only reach more than 40MB/s, indicating it's just a USB 2.0 cable.

Teardown

After reviewing this cable, let's take a closer look at its internal components and build quality.

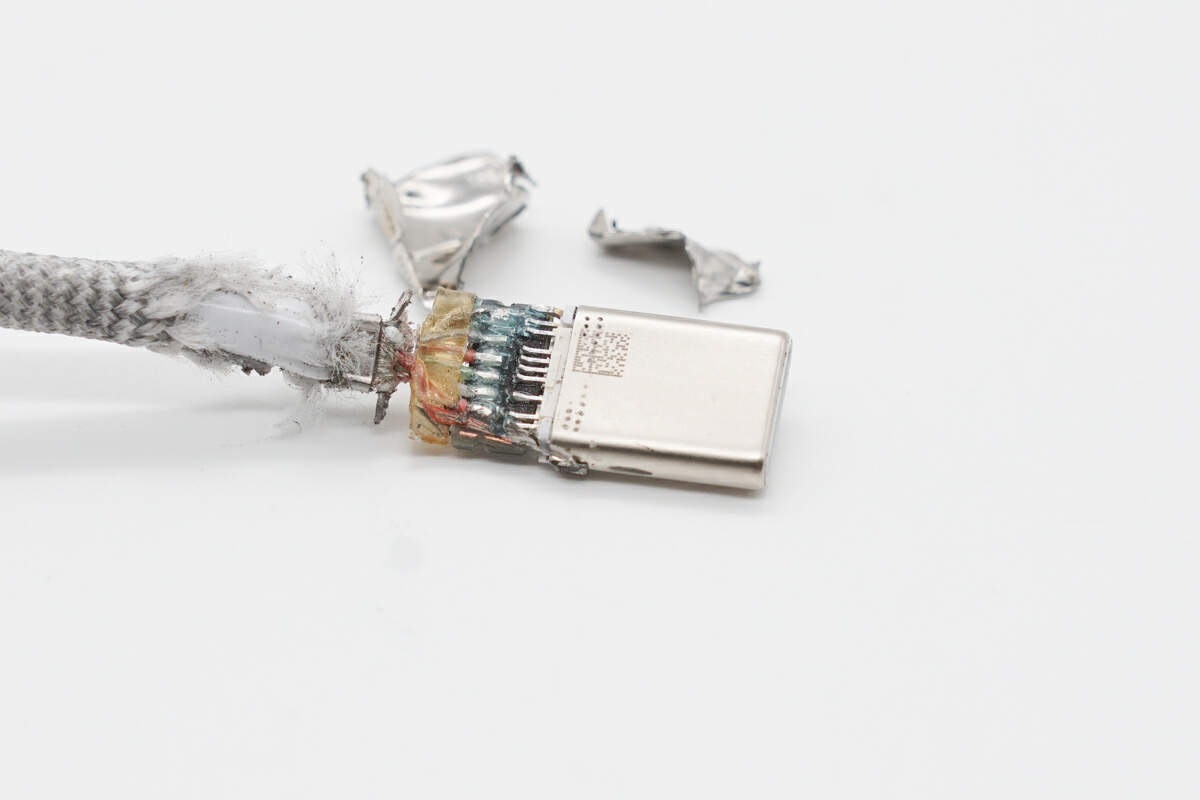

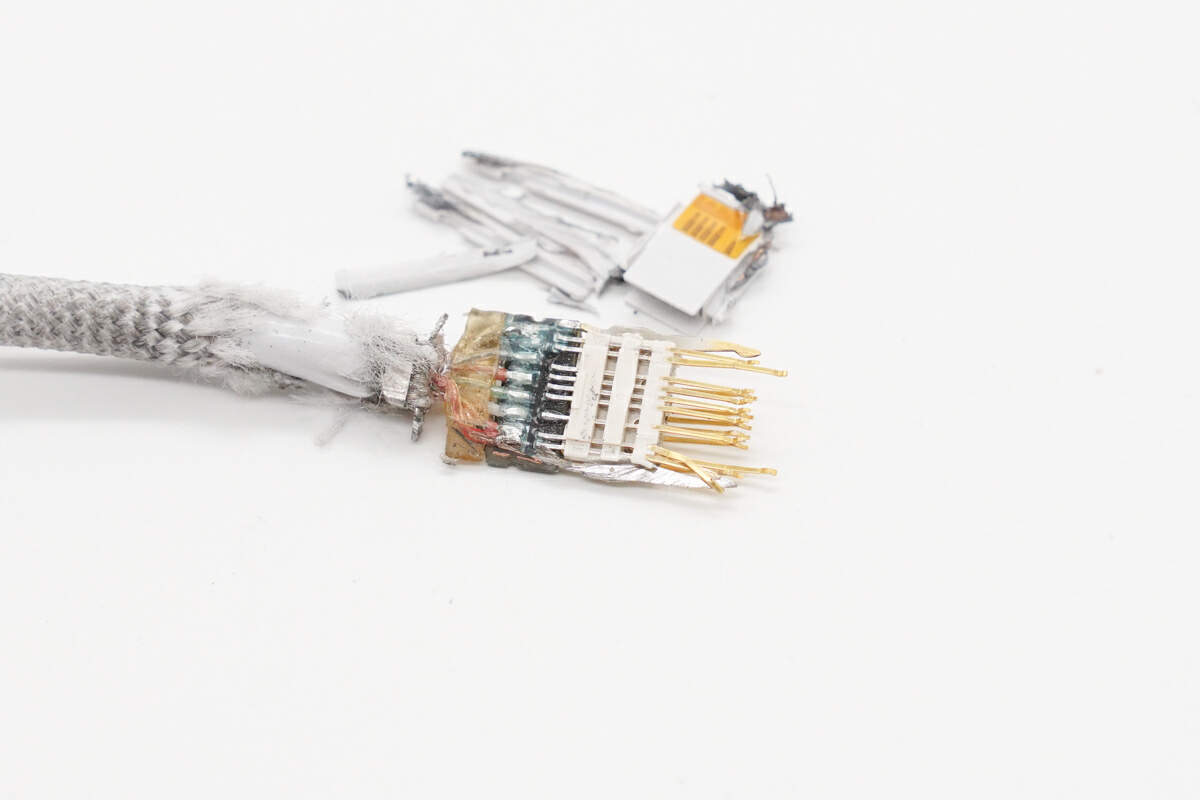

Firstly, use the cutting machine to cut off the USB-C connector.

The top and bottom of the steel sleeve are protected by potting compound and a plastic ring. And it is fixed by plenty of laser solder joints.

Continuing to remove the steel sleeve, there are several wires below the glue.

And there's a reserved space for the E-marker chip on the back.

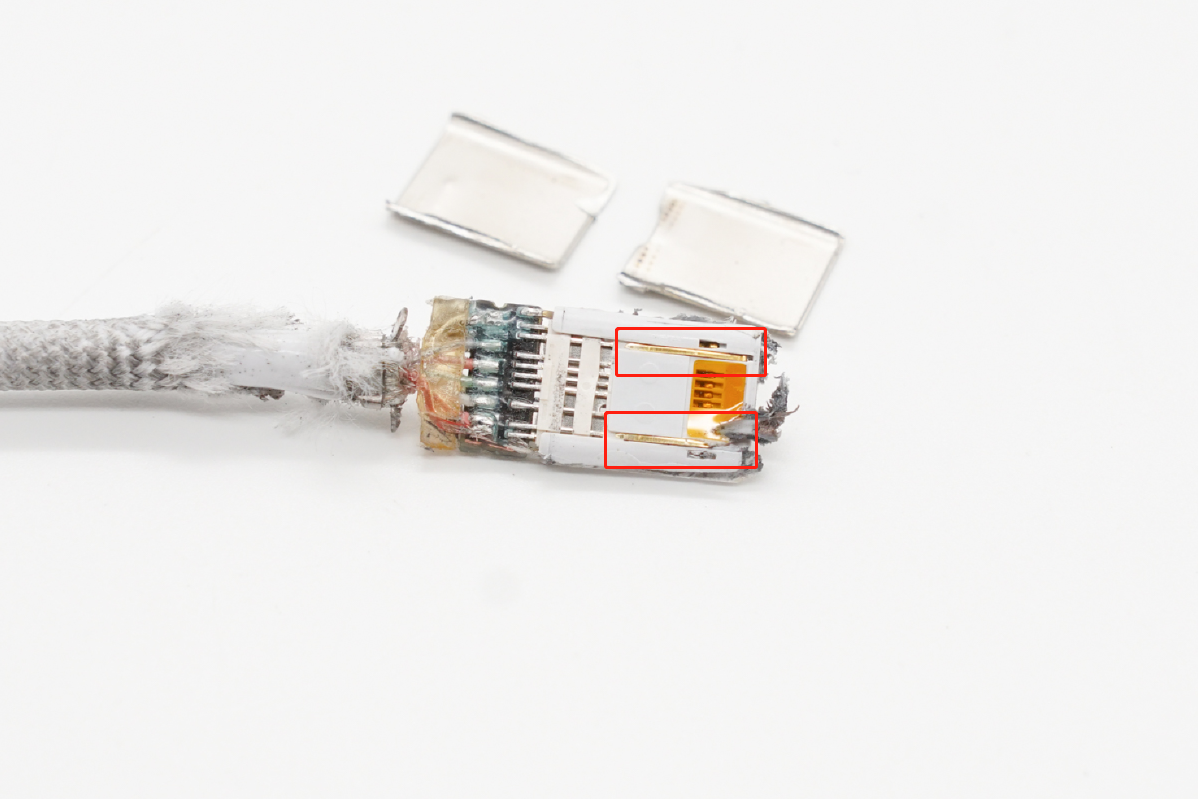

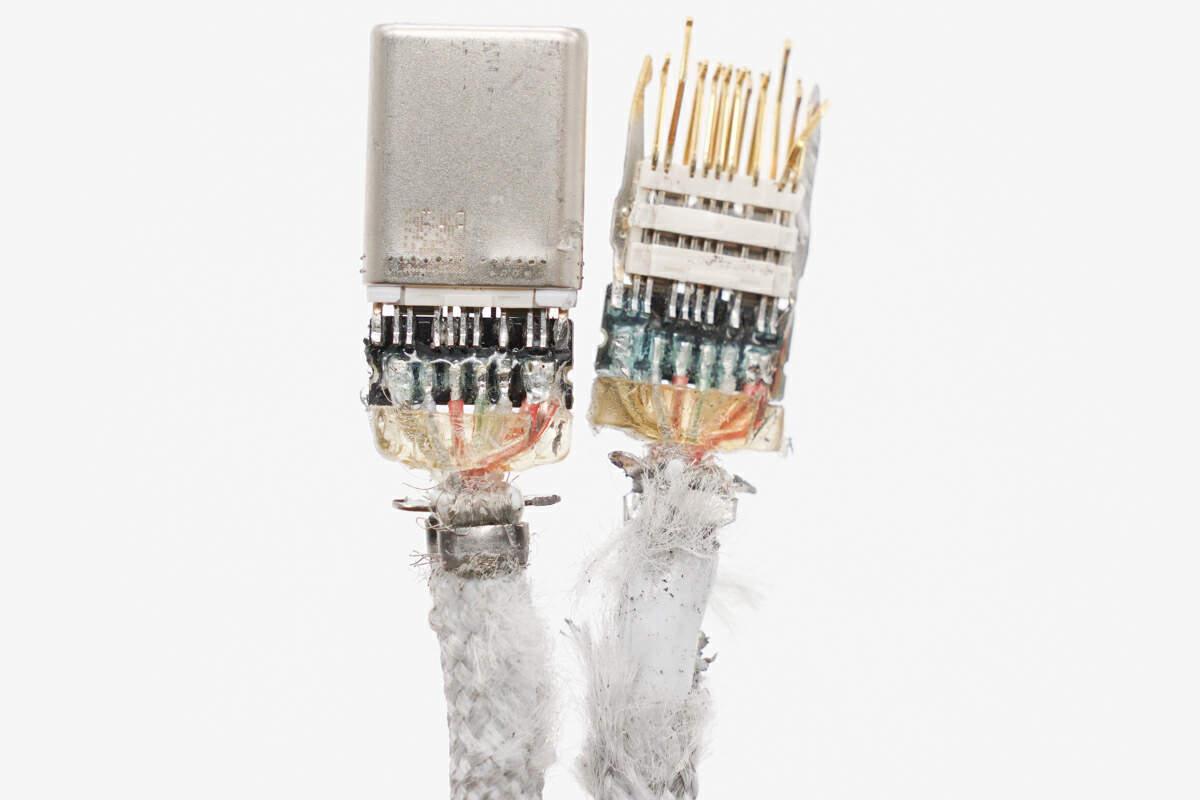

Next, we removed the metal shell of the USB-C connector, revealing two Apple-specific ground pins.

The gold-plated pins are beneath the plastic bracket.

The symmetrical design is pretty obvious.

The other connector have the exact same layout.

It also has a reserved space for the E-marker chip on the back.

Next, cut off the cable. The twisted structure on the woven layer causes it to gather together even after being cut.

There are a total of six wires inside. Three of them are colored red and serve as positive power supply wires, and that's why they have a thicker core. Meanwhile, the white and green wires are USB 2.0 wires. The thin blue wire on the left represents the CC wire, while the bare wire cores surrounding it function as negative pole wires.

Inside the woven layer, you'll find the TPE.

And there's a layer of shielding net under it.

There are some tensile fibers here to improve its durability.

Here is a close-up of the cable's internal structure, including the TPE, shielding net, power wire and data wire, as well as tensile fibers. Now let's take a more detailed look at the wire design inside the cable.

The core inside the positive power supply wire is made of tinned copper, and there are no tensile fibers.

The light blue CC wire also lacks tensile fibers.

This is the green D+ wire.

And the white one is the D- wire, they are used for USB 2.0 data transmission.

These six bare tinned copper wires are used for negative power supply.

This is the tensile fibers we talked about before.

Well, that would be all wires and components of this cable.

Summary of ChargerLAB

The included cables in the iPhone series have long had issues with durability, but the addition of a woven design significantly enhances their lifespan.

In terms of performance and build quality, it lacks an E-marker chip, supporting only 60W power transmission. Additionally, compared to the Apple 240W USB-C charge cable and the retail 60W USB-C charge cable , it lacks an aluminum foil layer. However, its overall build quality remains quite good, meeting the basic requirements for serving iPhones. So if you only plan to use it on your iPhone, you're good to go. Otherwise, maybe consider the 240W one or the Apple thunderbolt 4 pro cable.

Related Articles:

1. Limited to USB2.0? | Teardown of Apple 240W USB-C Charge Cable (2 m)

2. Let’s Test if the iPhone 15 Can Be Charged With Android Phone Chargers

3. Up to 60W | Teardown of Apple Original USB-C Cable For iPhone 15 Series (Video)