Introduction

On September 10th, Apple held its 2025 Fall Event, unveiling the iPhone 17 lineup alongside a brand-new product category—iPhone Air. Among the announcements, one product that stood out was Apple’s new 40W Dynamic Power Adapter, which gained attention for its compact design and ability to dynamically deliver up to 60W of total output power.

The charger is now available on Apple’s official website, priced at $39 USD. According to Apple, when used with an iPhone 17 series device, the adapter can charge the phone to 50% in approximately 20 minutes—offering significantly faster charging performance compared to the previous generation. Despite the substantial power upgrade, the adapter maintains a highly compact form factor—roughly the same size as Apple’s standard 20W charger. It also features foldable prongs for improved portability and travel convenience. In the following teardown, we take a closer look at the internal design and power distribution architecture of Apple’s latest fast charger.

Product Appearance

The front of the packaging features the Apple logo, product name, and an image of the adapter.

The back of the packaging displays a simplified diagram of the adapter and its ports, along with CE certification and other information.

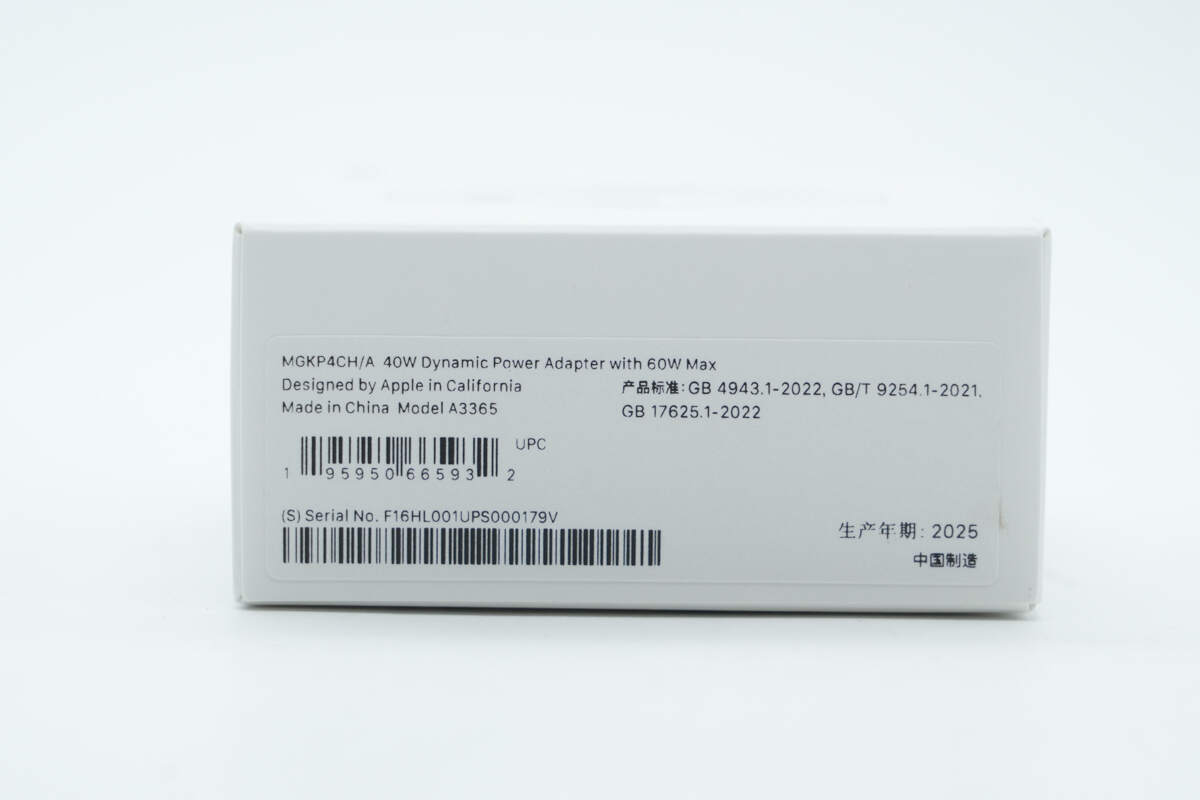

One side of the packaging has a specification label attached.

The opposite side features a label indicating the manufacturing date and "Made in China" origin.

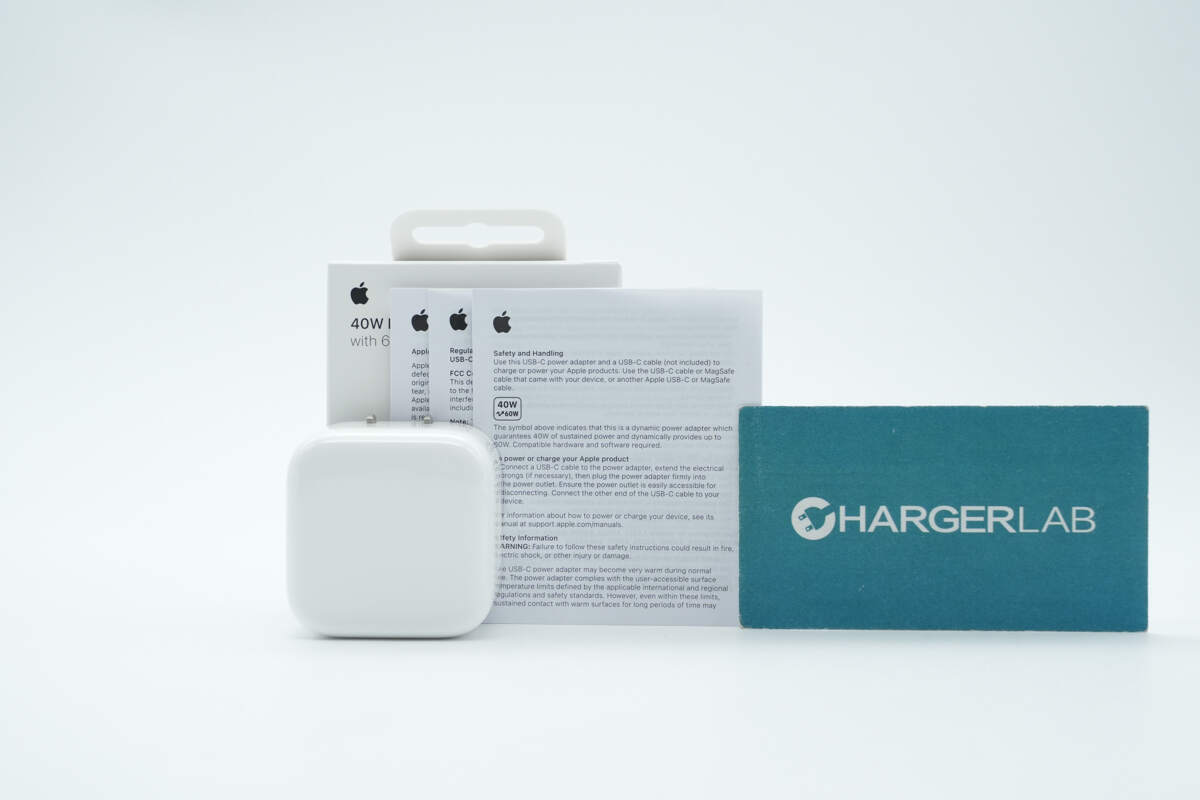

The packaging includes the charger along with the user manual and other documentation.

The charger is wrapped in protective paper.

It features a design similar to the 35W dual USB-C charger (model A2579).

The small recessed areas on both sides of the body facilitate easy plugging and unplugging.

The output side features a single USB-C port with a white plastic insert.

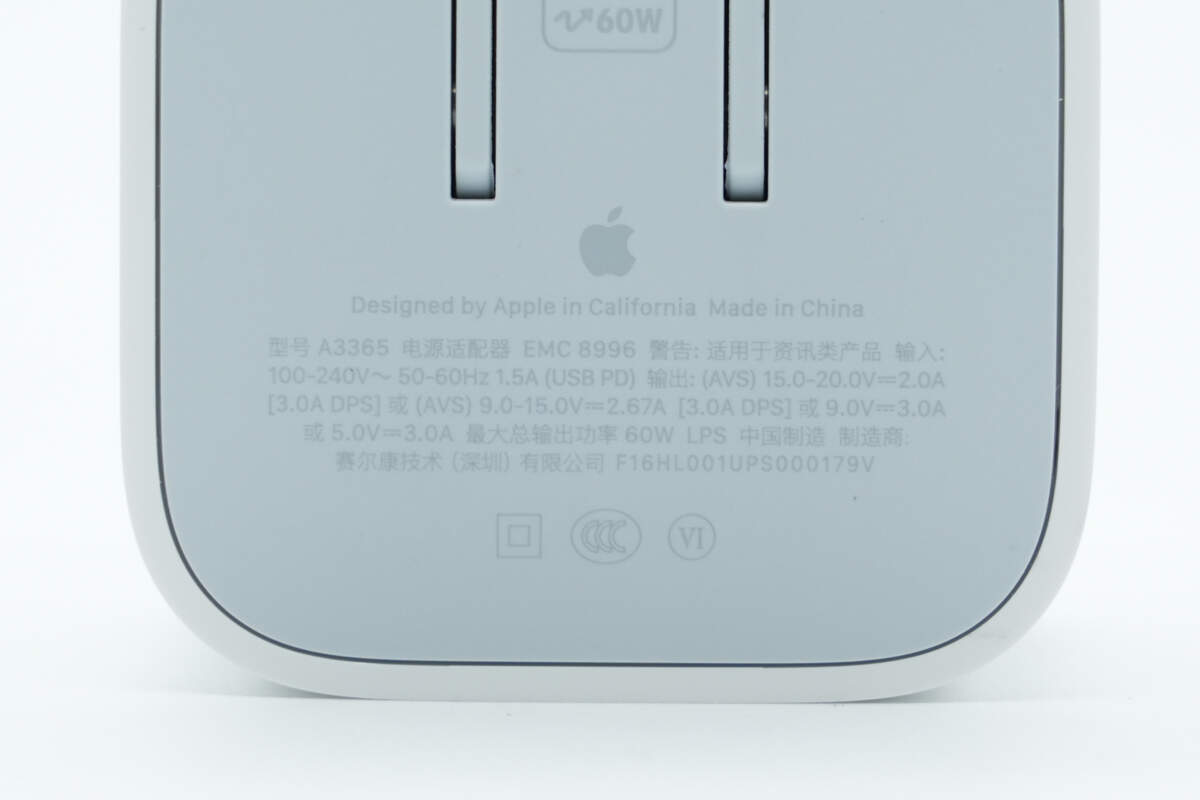

The bottom is printed with specification details.

Model: A3365

Input: 100-240V\~ 50/60Hz 1.5A (USB PD)

Output: (AVS) 15-20V 2A \[3.0A DPS] or (AVS) 9-15V 2.67A \[3.0A DPS] or 9V 3A or 5V 3A

Maximum total output power: 60W LPS

The charger has passed CCC certification and Level VI energy efficiency certification.

It features foldable prongs.

The length of the charger is about 45.72 mm (1.8 inches).

The width is about 45.73 mm (1.8 inches).

The thickness is about 28.11 mm (1.11 inches).

Its size is nearly identical to that of the Apple 20W charger.

It is slightly smaller than the 35W dual USB-C charger.

That's how big it is in the hand.

The weight is about 80 g (2.82 oz).

ChargerLAB POWER-Z KM003C shows that it supports PD3.0 and DCP charging protocols.

And it has four fixed PDOs of 5V3A, 9V3A, 15V2.67A, and 20V2A.

When used to charge the iPhone 16 Pro Max, the charging power is about 27.23W.

When charging the MacBook Air M3 2024, the charging power is about 55.94W, successfully activating the 60W dynamic fast charging feature.

Teardown

Next, let's take it apart to see its internal components and structure.

Remove the bottom casing, and it is revealed that the enclosure uses a combination of snap-fit clips and ultrasonic welding for sealing.

The input side features a contact-based power delivery design. The inner side of the casing is lined with a graphite thermal pad and has been treated for insulation.

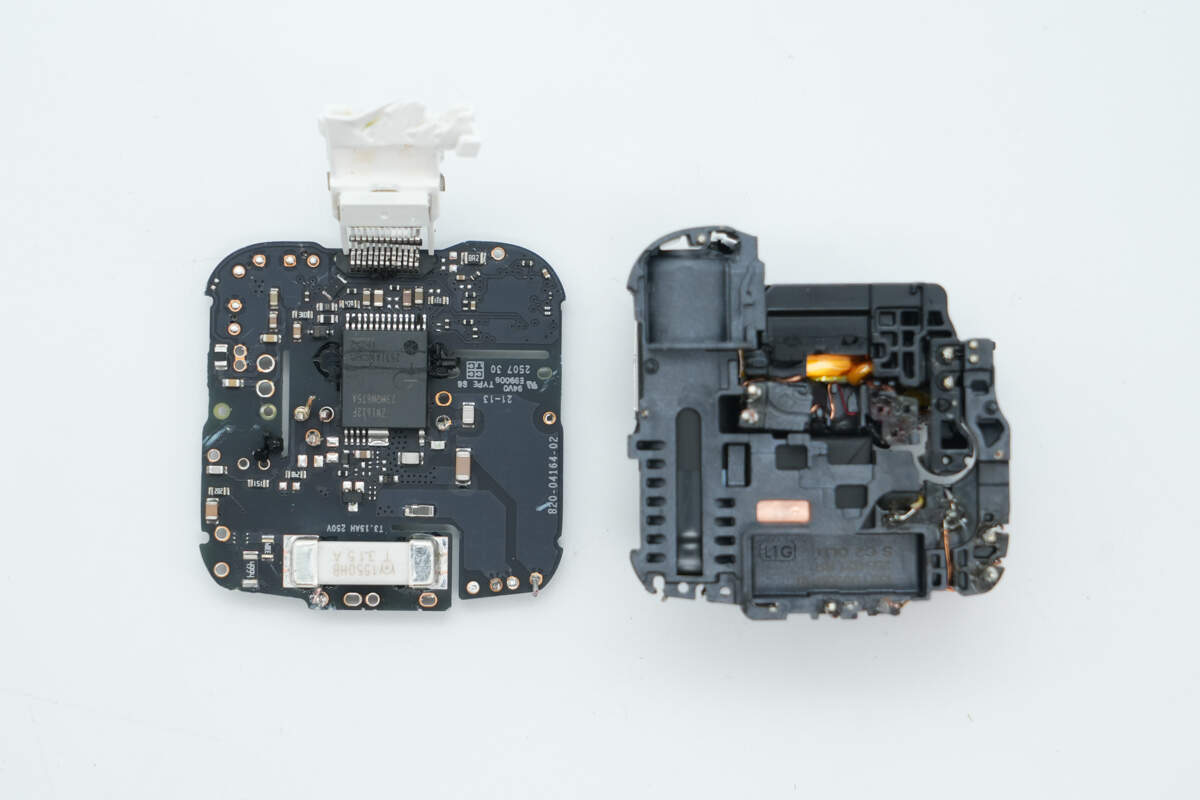

Remove the PCBA module.

The inner side of the other half of the casing is lined with the graphite thermal insulation pad and the protective rubber cushion.

High-temperature resistant insulating tape is also applied along the sides.

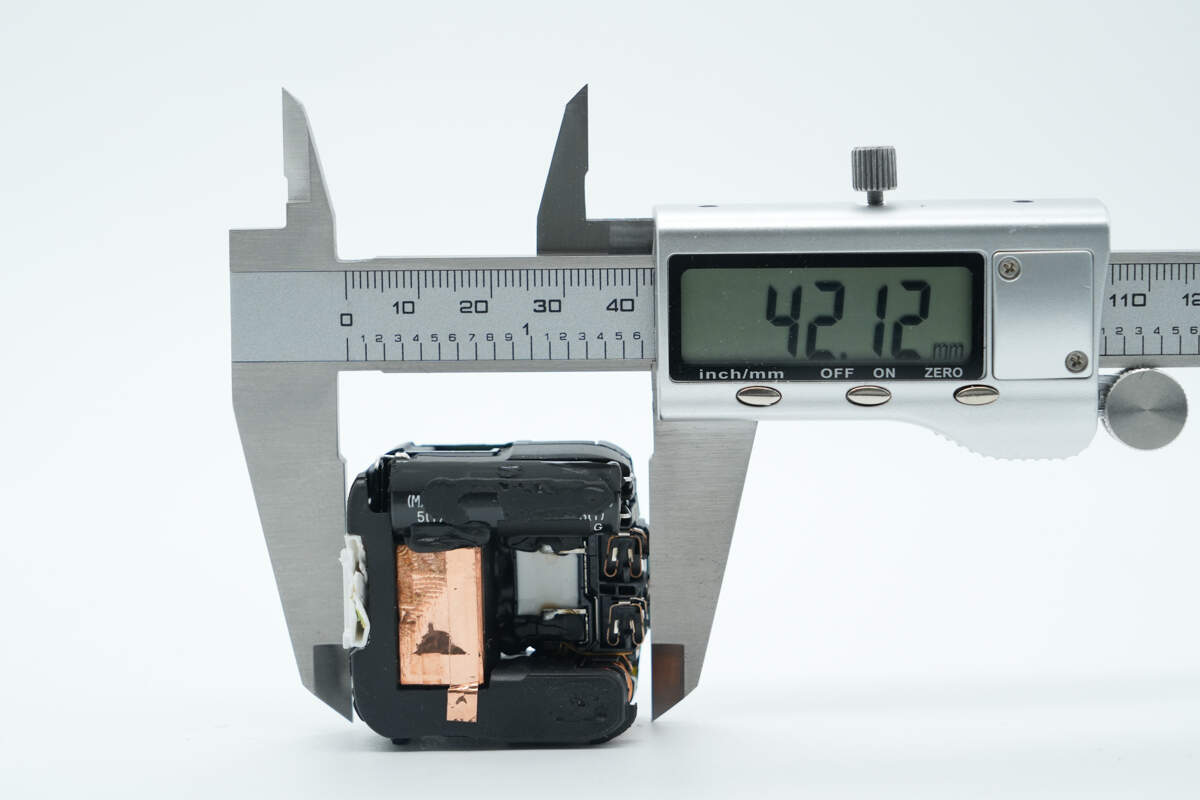

The length of the PCBA module is about 42.12 mm (1.66 inches).

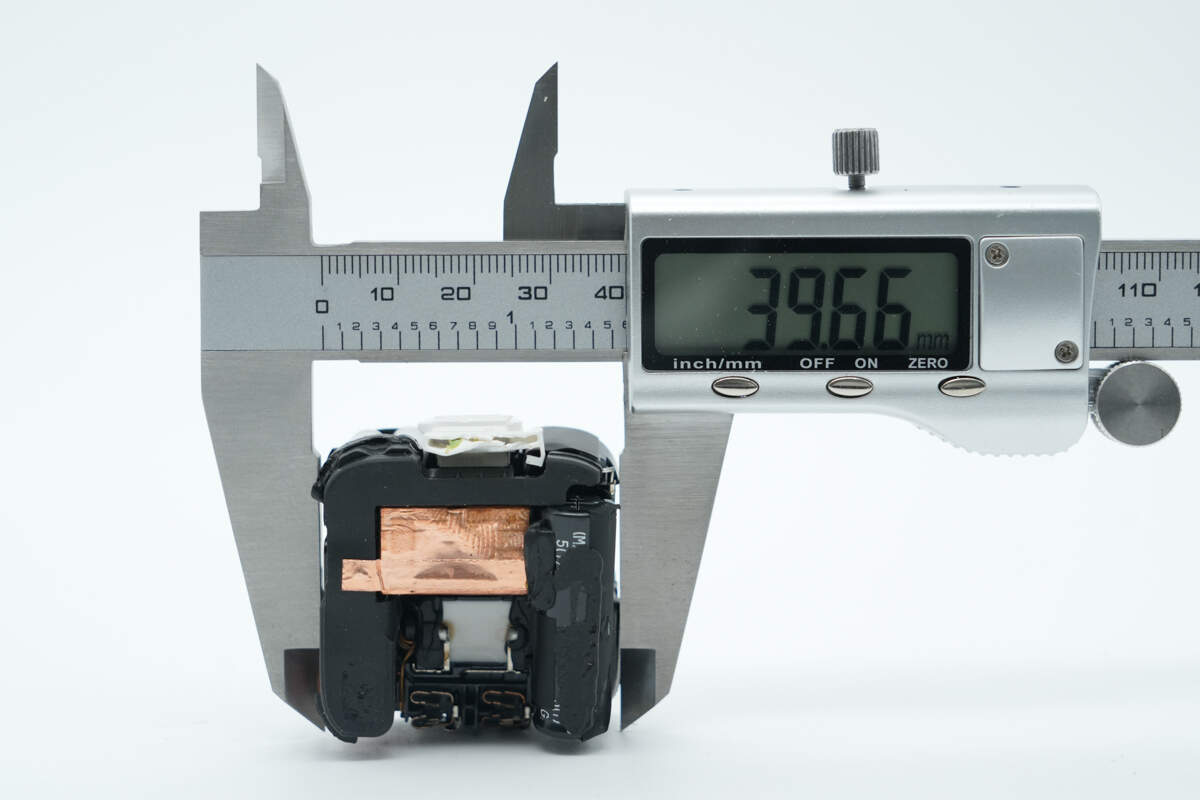

The width is about 39.66 mm (1.56 inches).

The thickness is about 23.27 mm (0.92 inches).

One side of the PCBA module and the top of the output end are covered with protective foam pads.

A protective pad is also placed between the two high-voltage electrolytic filter capacitors on the other side.

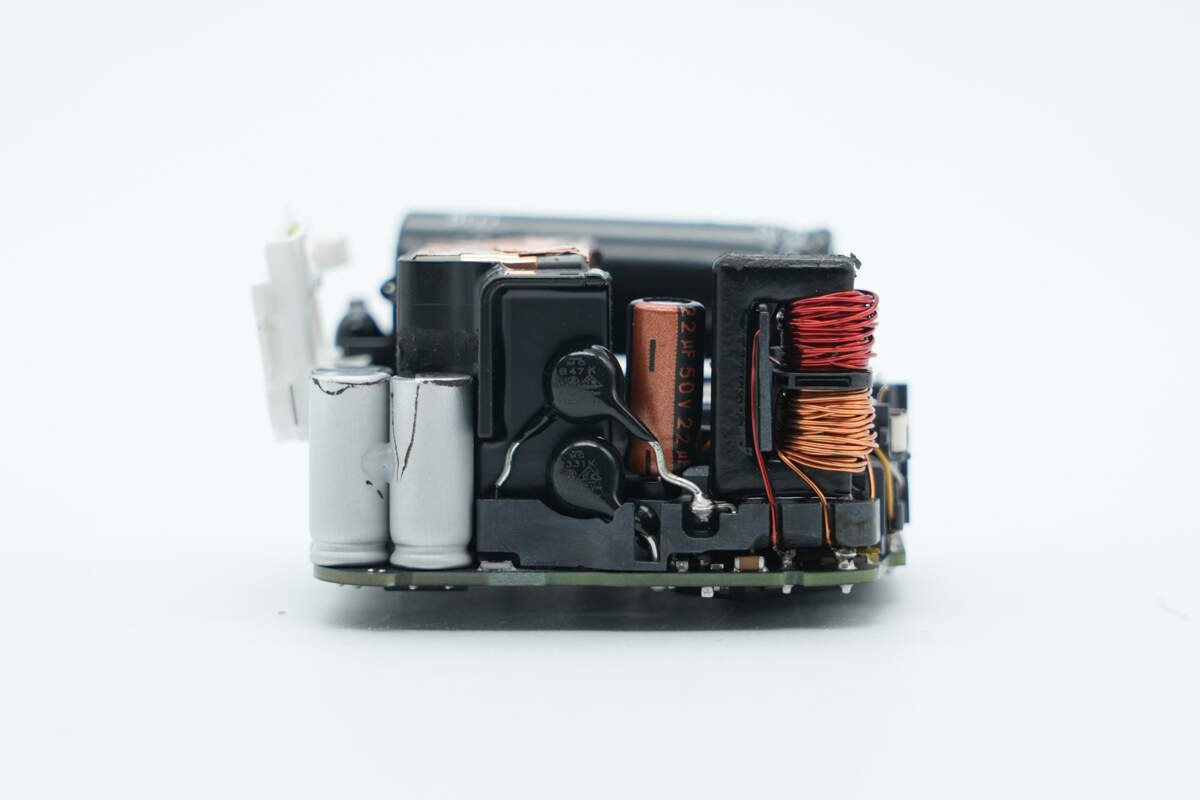

The top-mounted high-voltage electrolytic filter capacitor and the transformer are secured with adhesive for added stability and insulation.

The solid capacitors for output filtering are also secured with adhesive, and an insulating sheet is attached to the left side of the plastic casing.

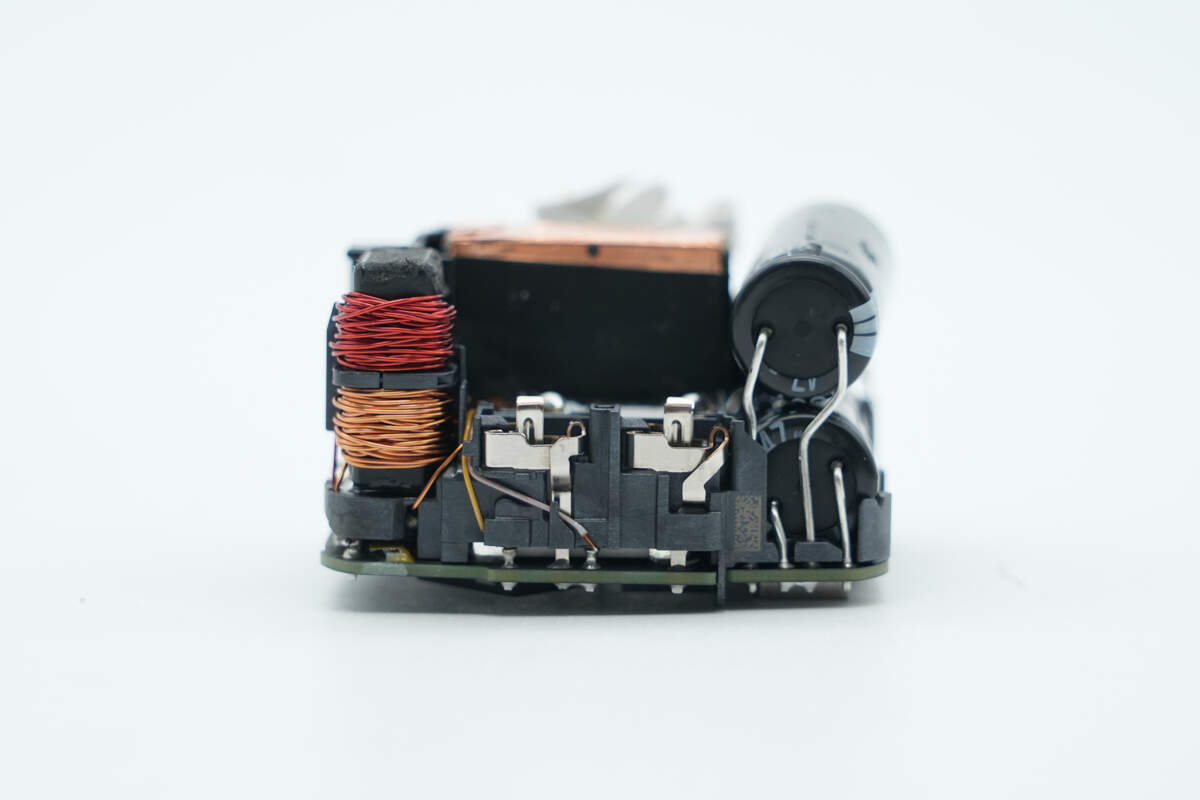

Remove the foam pads and black adhesive. The transformer is wrapped in copper foil, and the side near the secondary winding is reinforced and insulated with a plastic casing.

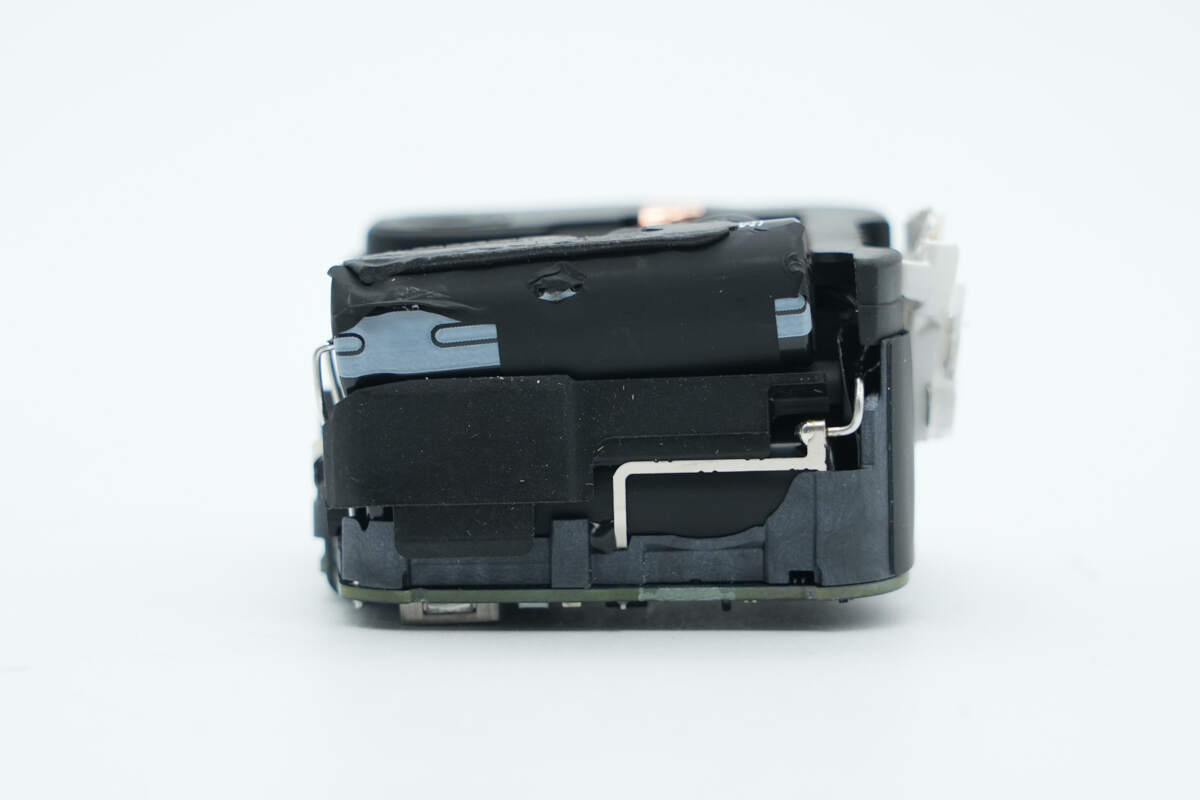

The PCBA module's input side features metal contact plates for power delivery along with a supporting plastic frame.

This side contains common mode chokes, a capacitor supplying power to the master control chip, and Y capacitors.

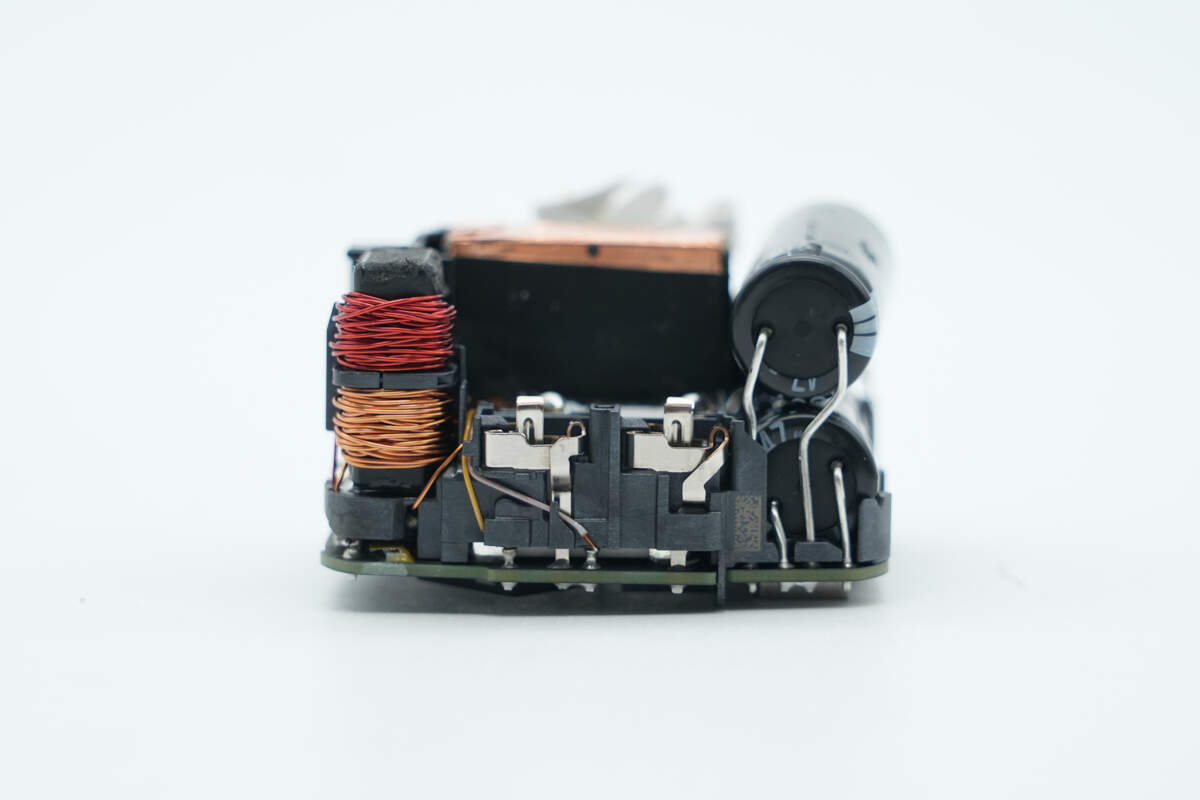

On the opposite side, two high-voltage electrolytic capacitors are mounted horizontally.

On both sides of the output, there are Y capacitors and solid capacitors, respectively.

Remove the capacitors, transformer, and other components. A plastic bracket is installed at the bottom to provide support and isolate the PCB.

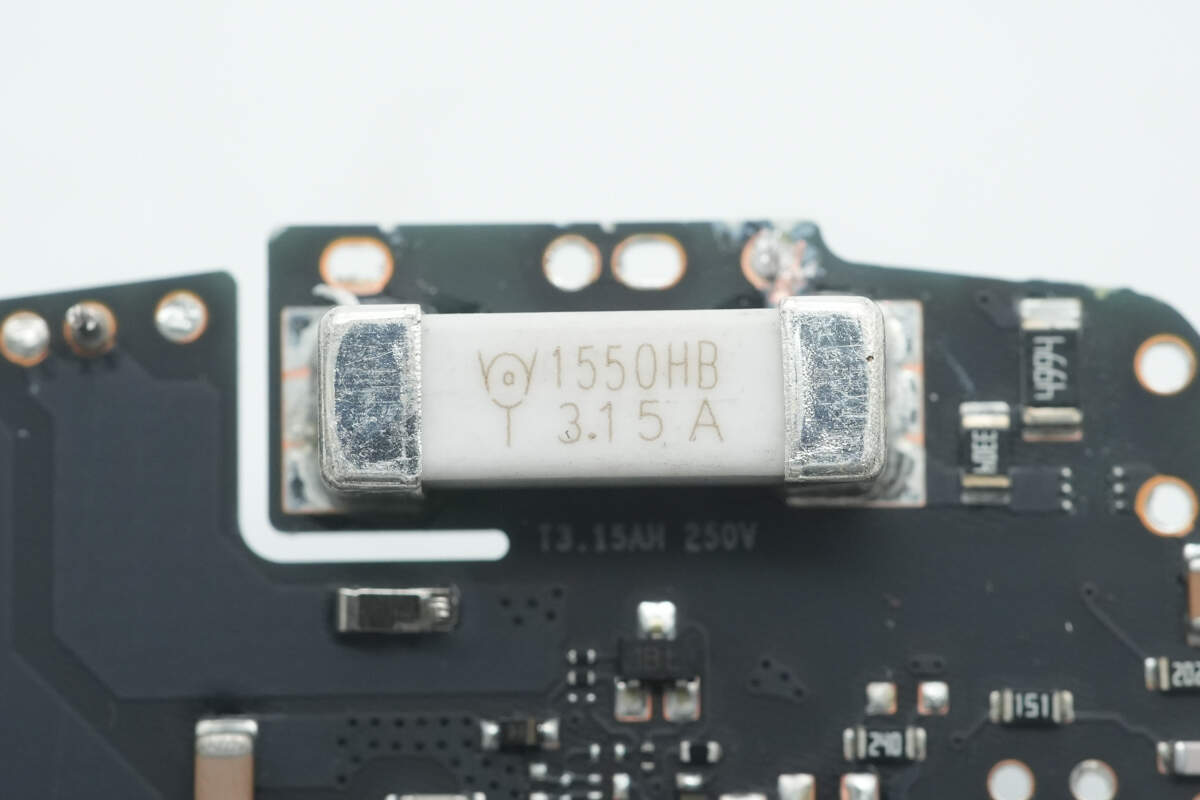

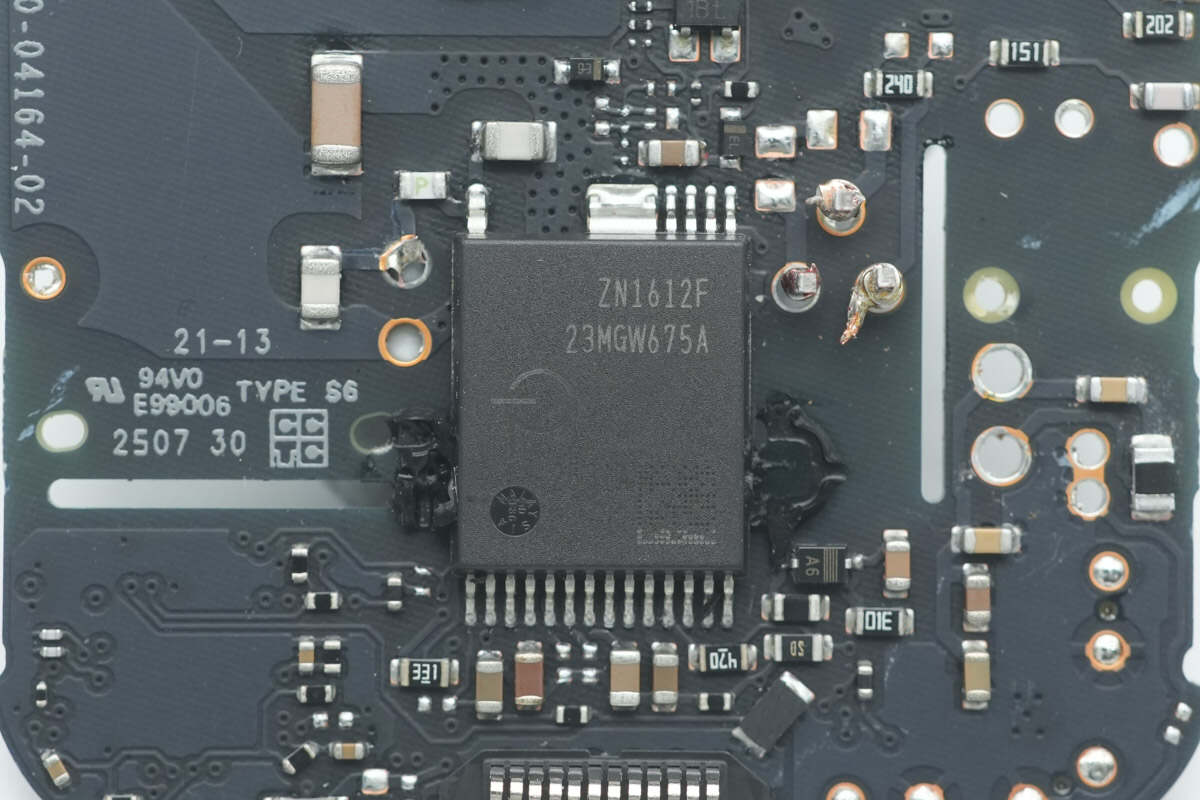

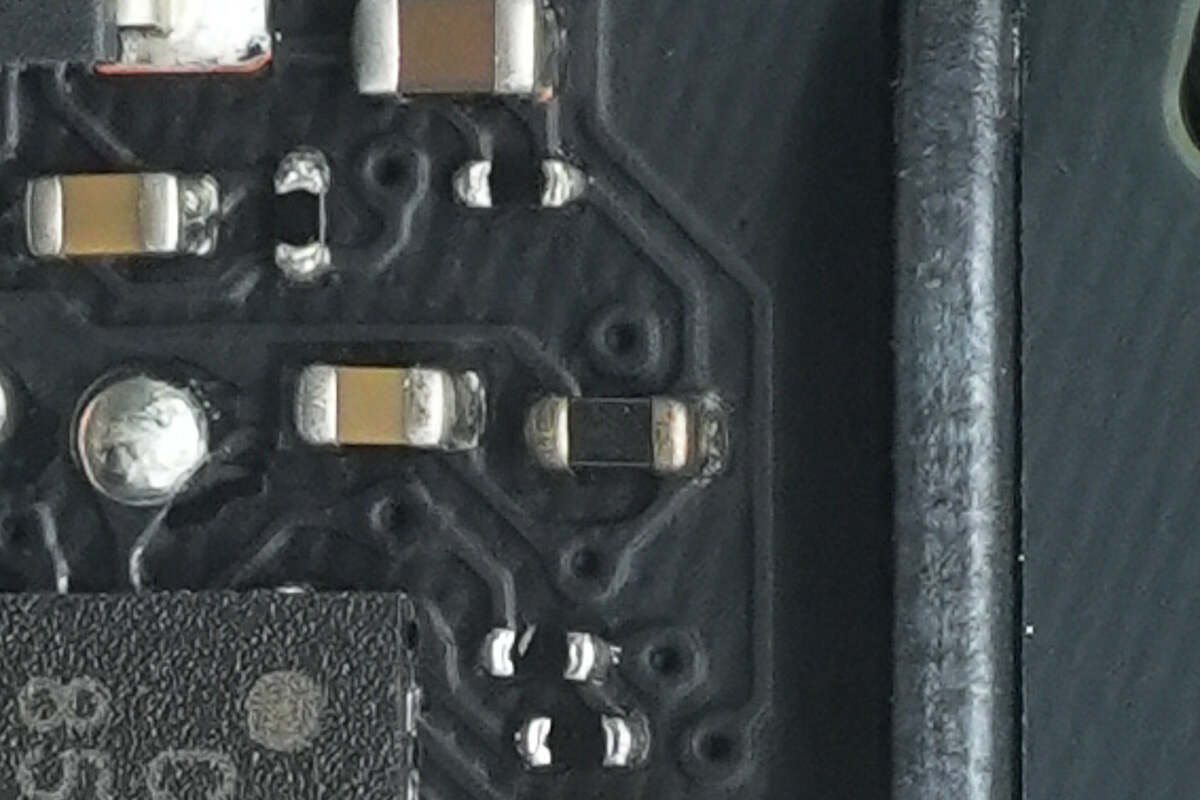

The front side of the PCB features an SMD fuse and the master control chip.

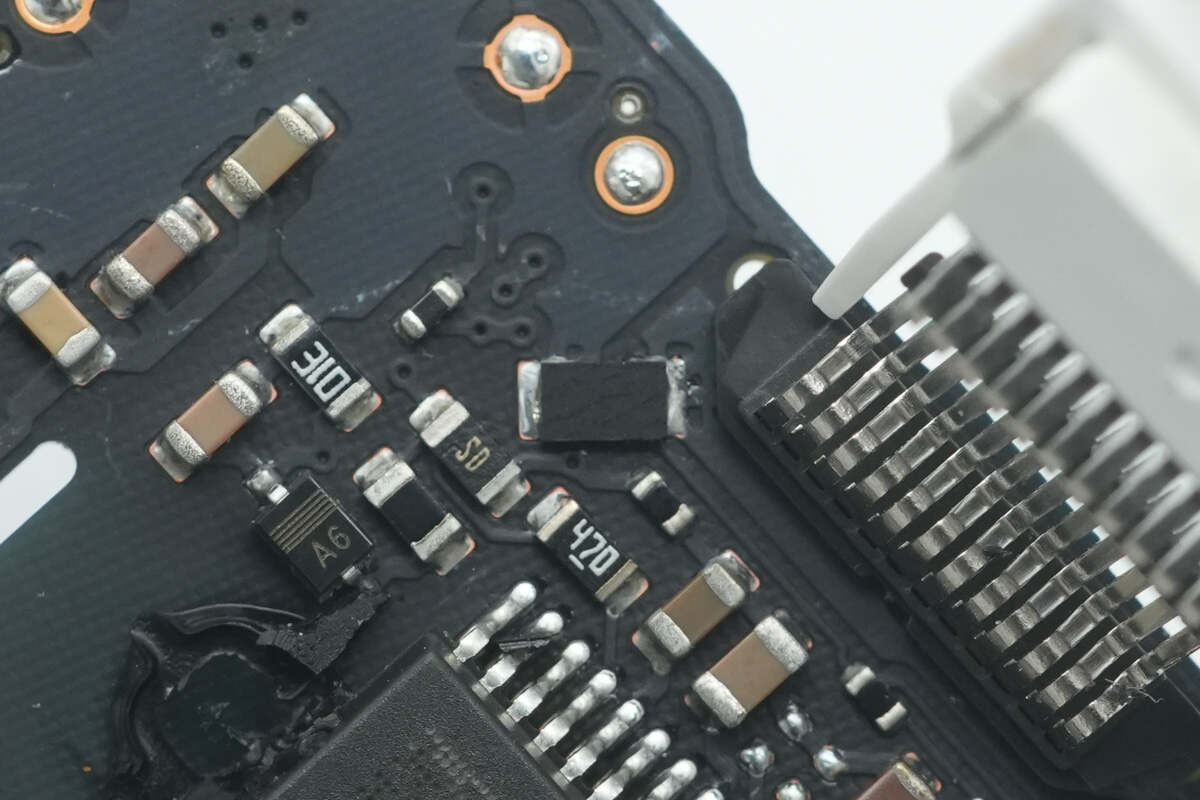

The back side of the PCB contains the bridge rectifier, differential mode choke, synchronous rectifier, protocol chip, and output VBUS MOSFET.

Disassemble the capacitors, transformer, and other components. Let’s take a closer look at the specifications and functions of these individual components.

The SMD fuse is from WalterFuse with a rated current of 3.15A.

The two common mode chokes are arranged in a two-stage design to more effectively filter out EMI interference.

The safety X2 capacitor is wrapped with copper foil for shielding.

It has a specification of 0.1μF.

It is connected via soldered copper strips.

The input-side bridge rectifier is from DIODES, model RTT10KL, and uses a TTL package.

The high-voltage filter capacitors are from NCC, each rated at 400V 47μF, connected in parallel.

The differential mode choke has a specification of 13μH.

The master control chip is from PI, marked with ZN1612F, a custom model for Apple. It integrates the primary controller, high-voltage MOSFET, synchronous rectifier controller, and feedback functions, offering high integration and reduced external components. This simplifies fast charging power circuit design. The chip uses an InSOP-T28D package.

The capacitor supplying power to the master control chip is from Lelon.

It is rated at 50V, 22μF.

The transformer is manufactured by Sumida.

Close-up of three black Y capacitors.

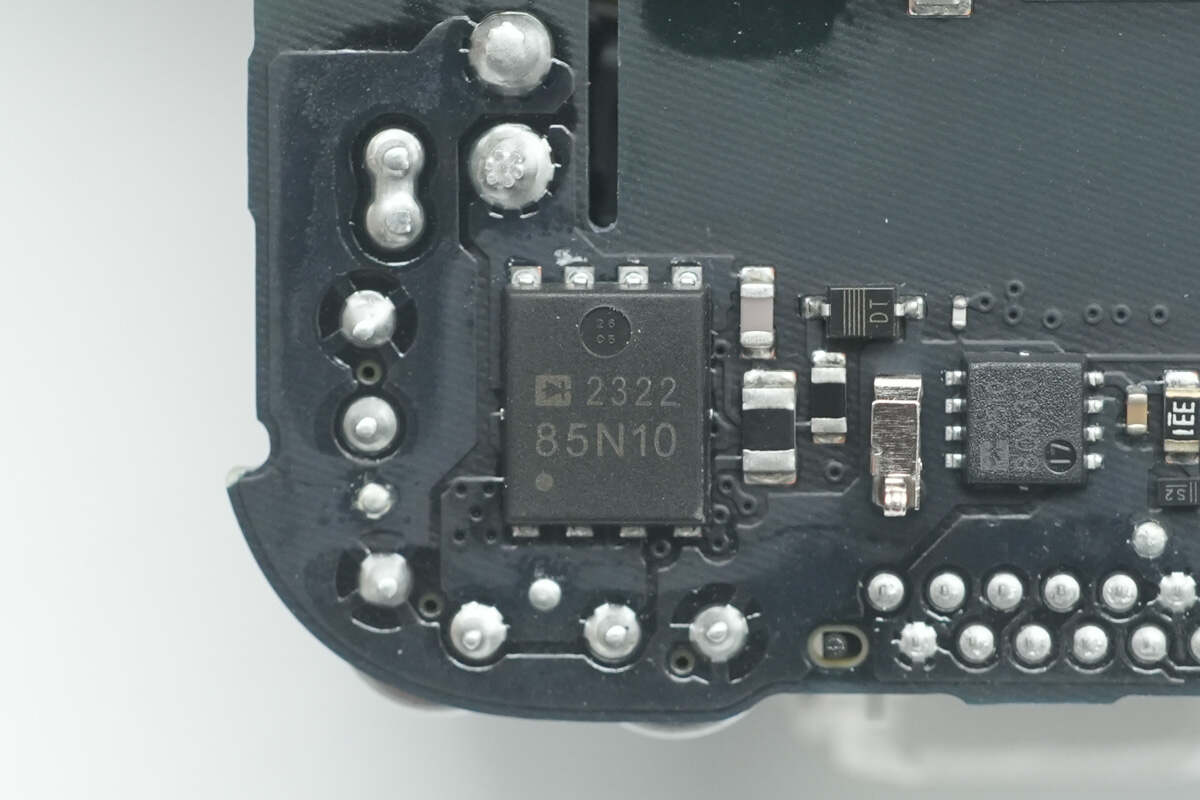

The synchronous rectifier is from RECTRON, model RM85N100DF. It is an NMOS transistor with a voltage rating of 100V and an on-resistance of 4.6mΩ, packaged in a DFN 5x6-8L form factor.

The three solid capacitors for output filtering are from Nichicon, each rated at 25V 270μF.

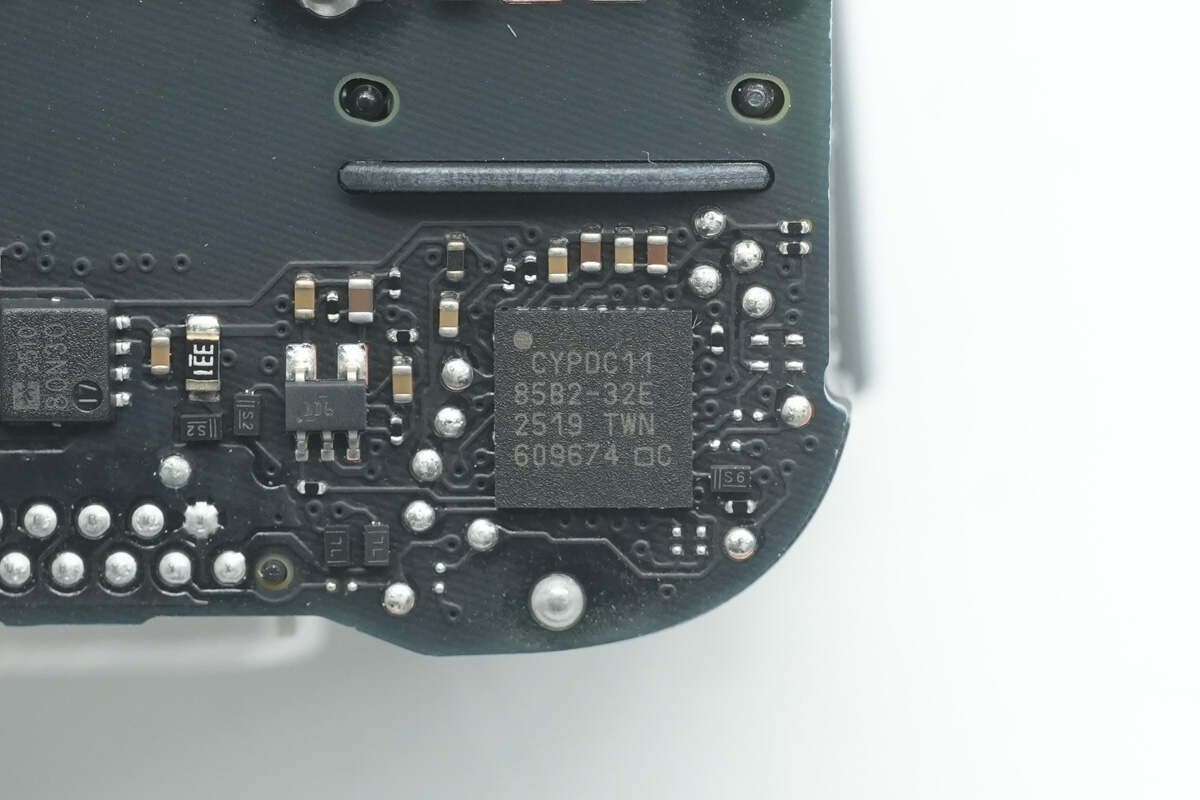

The protocol chip is from Infineon, model CYPDC1185B2-32E, housed in a 32-pin QFN package.

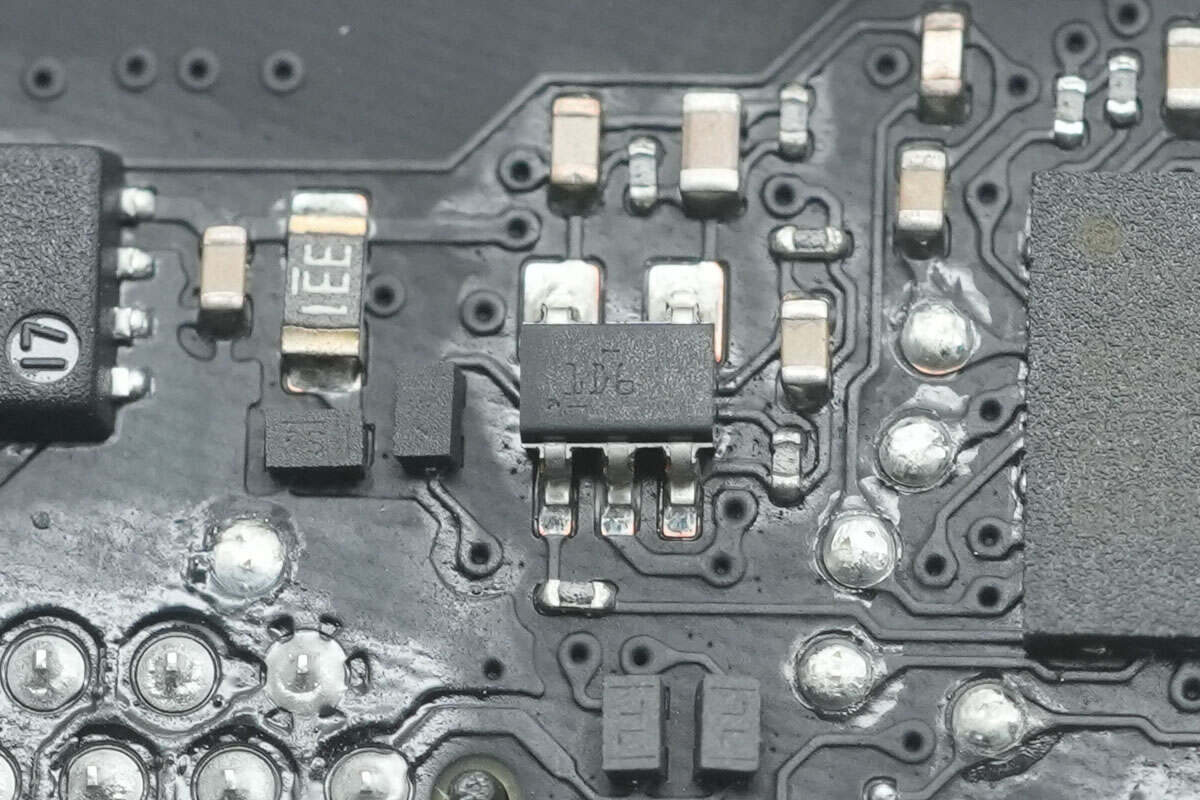

The TI TLV9001 is a single-channel, 1MHz, rail-to-rail input and output operational amplifier with a voltage range of 1.8–5.5V, packaged in a SOT-23 (5) form factor.

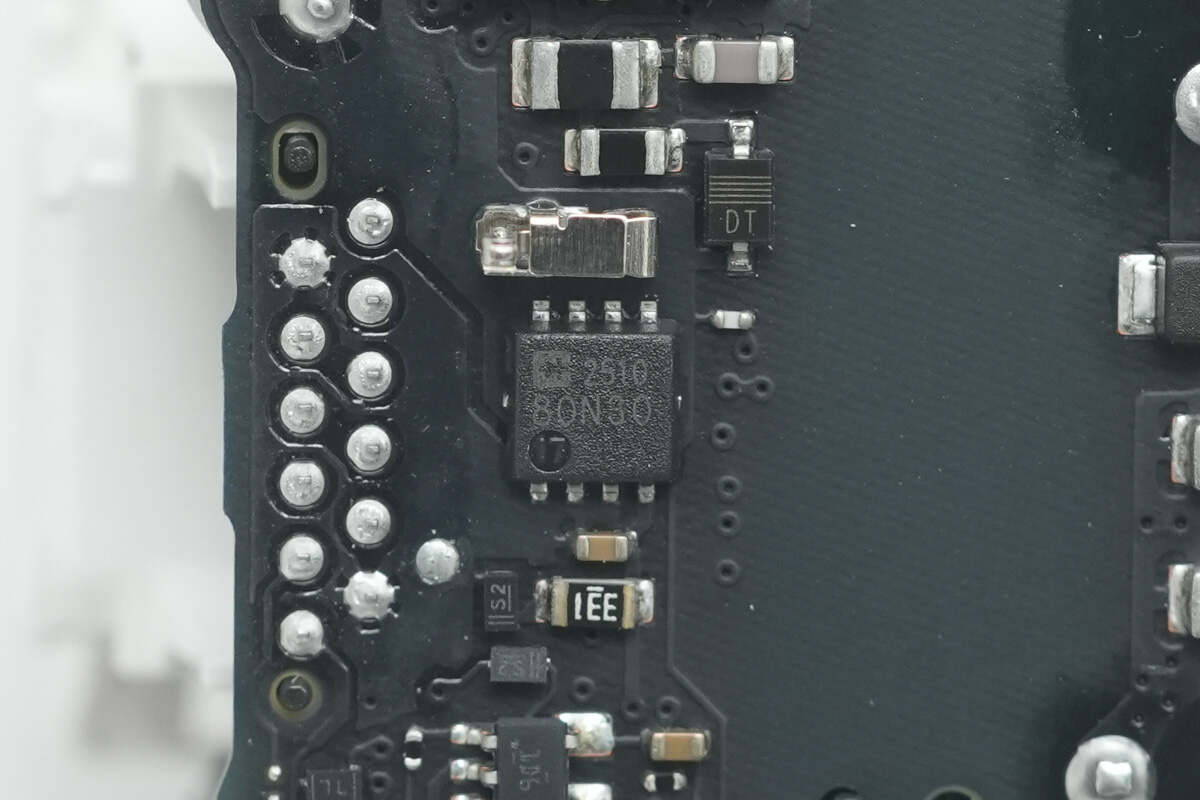

The VBUS MOSFET is also from RECTRON, model RM80N30DN. It is an NMOS transistor rated for 30V with an on-resistance of 3.8mΩ, packaged in a DFN 3x3 form factor.

The thermistor monitors the internal temperature and dynamically adjusts the power level to reduce output power when the temperature rises.

Close-up of the sampling resistor used to detect the output current.

The pins of the USB-C socket are extended and soldered onto the PCBA.

Well, those are all components of the Apple 40W Dynamic Power Adapter with 60W Max.

Summary of ChargerLAB

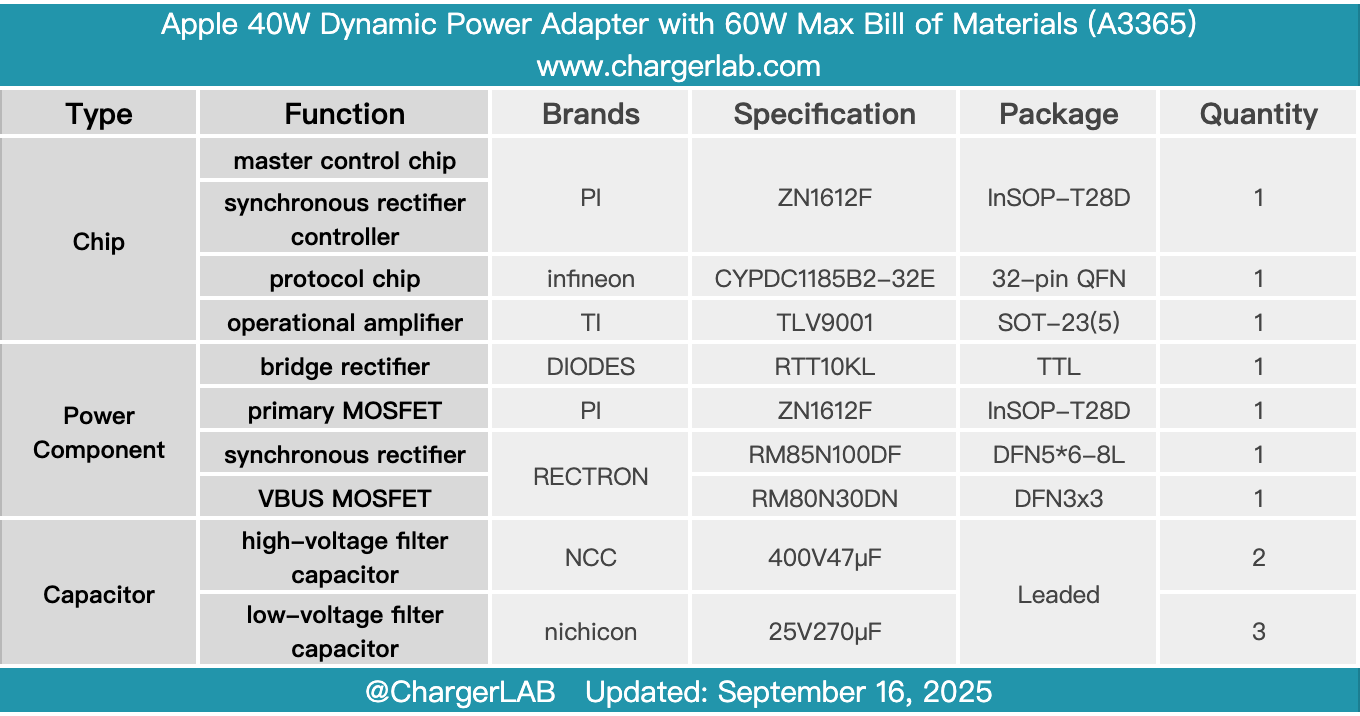

Here is the component list of the Apple 40W Dynamic Power Adapter with 60W Max for your convenience.

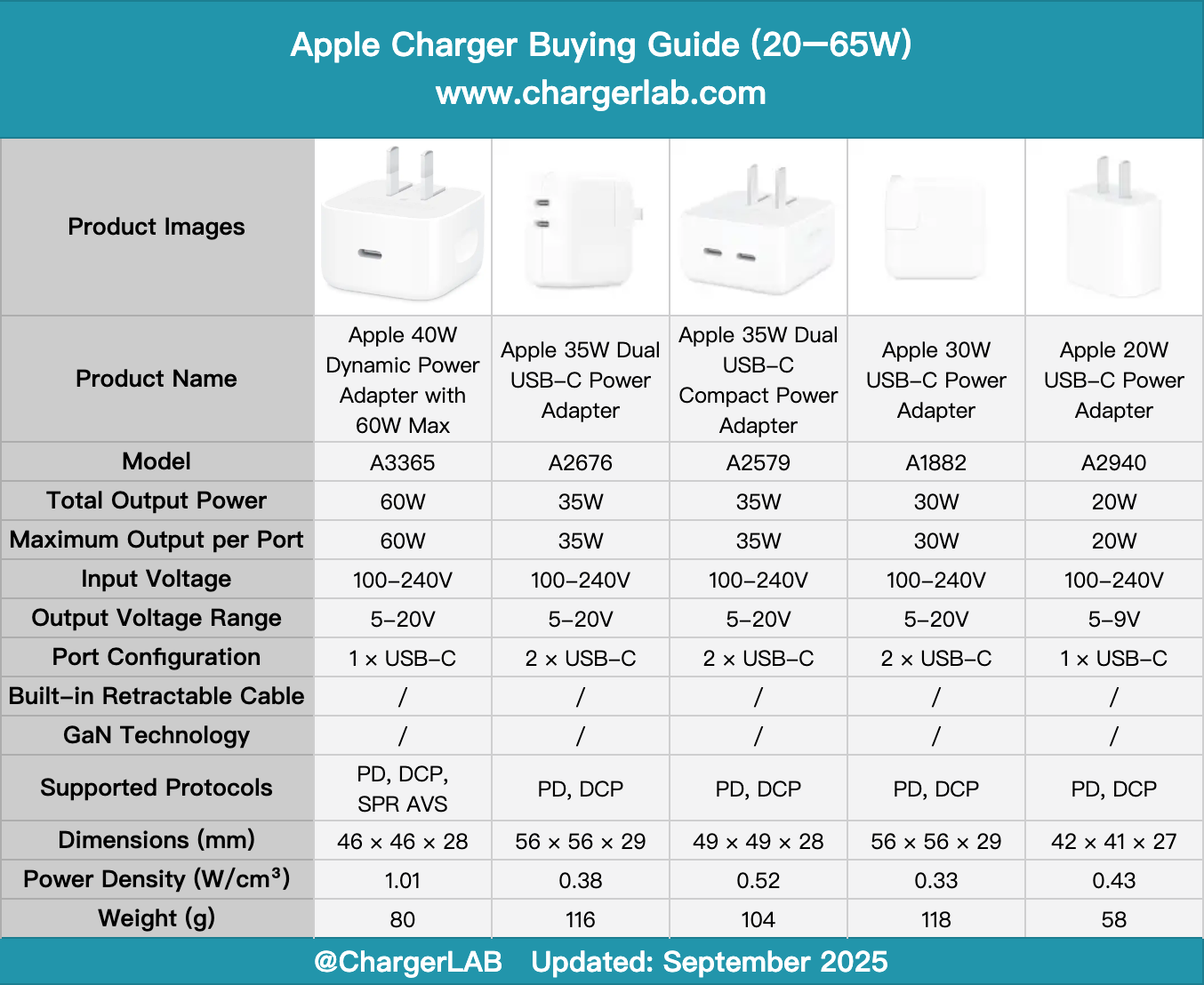

It features a design similar to the 35W dual USB-C charger and comes with foldable prongs. The unique dynamic power delivery can be understood as "peak 60W, stable 40W," intelligently adjusting output power based on the device’s needs. This ensures it meets the charging requirements of the iPhone while also accommodating high-power charging scenarios for the MacBook. Given the increased charging power of the iPhone 17 series, this new adapter is definitely worth considering for new device users.

After taking it apart, we found that it uses the highly integrated PI power chip ZN1612F, paired with the RECTRON RM85N100DF synchronous rectifier. The output is controlled by an Infineon CYPDC1185B2-32E protocol chip, with filtering handled by capacitors from NCC and Nichicon.

The internal thermistor monitors the internal temperature to enable dynamic power switching. The charger’s casing remains robust as usual, with graphite thermal pads and foam cushions applied on the inside to assist with heat dissipation and protection. The PCBA module is further reinforced and insulated with foam pads and a plastic bracket, demonstrating reliable workmanship.

Related Articles:

1. Apple iPhone 17 Series Debuts With 40W Dynamic Power Adapter and PD 3.2 AVS Fast Charging

2. Hands-On Guide: ChargerLAB POWER-Z KM003C Load Test of Apple’s 40W Dynamic Power Adapter

3. What's Difference Between Two Apple 35W Charger (Compact and Traditional)