Introduction

Laifen has recently introduced a new-generation sweeping & vibrating electric toothbrush, the i2. To address different aesthetic preferences and user needs, the i2 is available in three versions: ABS, transparent, and aluminum alloy. The transparent version features a high-transparency PC housing with an AF anti-fingerprint coating, presenting a bottom-to-top gradual transparency that reveals the precision internal structure.

The i2 electric toothbrush supports Bluetooth connectivity to a mobile app, allowing users to personalize sweeping amplitude and vibration speed. It also incorporates multiple user-centric design features. The vibration frequency reaches up to 66,000 movements per minute, and a PID dynamic compensation algorithm is employed to address performance attenuation, further enhancing the overall user experience.

Notably, the toothbrush adopts a magnetic wireless charging solution and is equipped with a 15W magnetic wireless charging base. Below, we take a closer look at this product.

Product Appearance

On the front of the packaging box, an image of the product’s exterior is printed.

A product information label is affixed to the bottom of the packaging box.

The package includes the electric toothbrush, a wireless charging base, two brush heads, an operation guide, and a product manual.

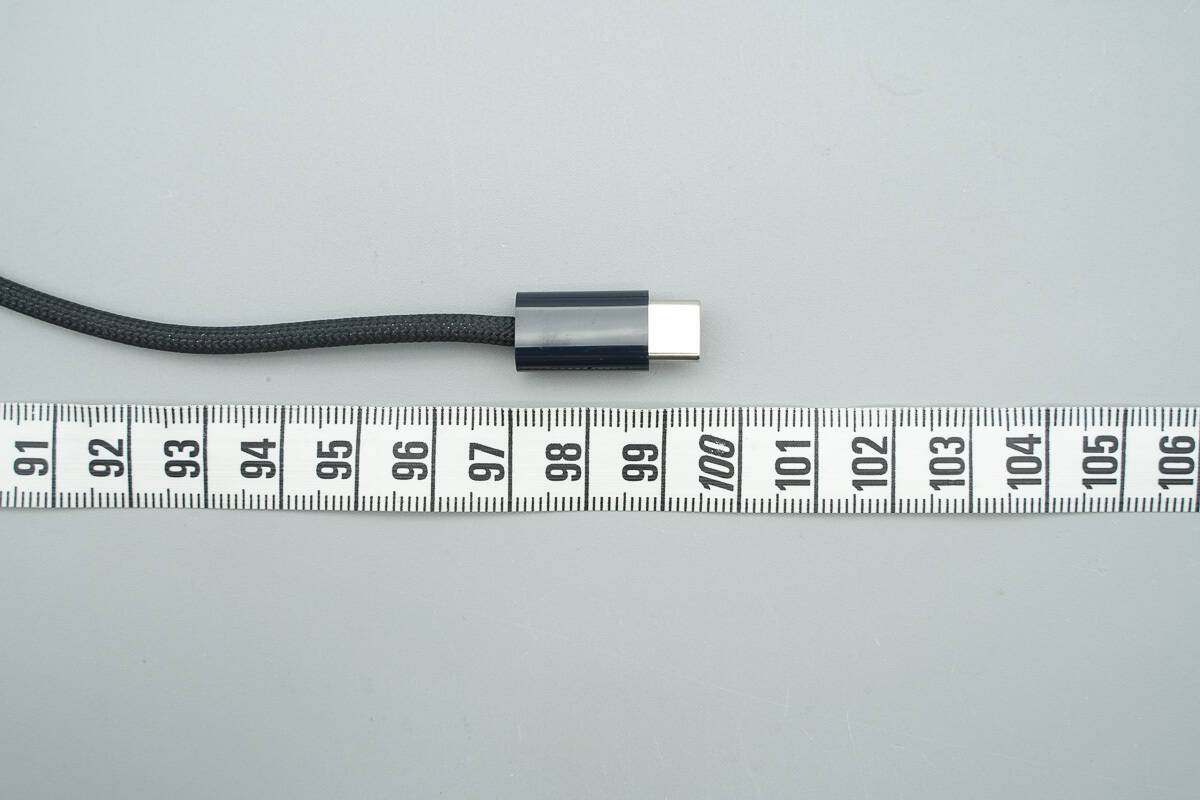

The wireless charging base comes with an integrated USB-C braided cable.

The USB-C cable connector features a glossy finish.

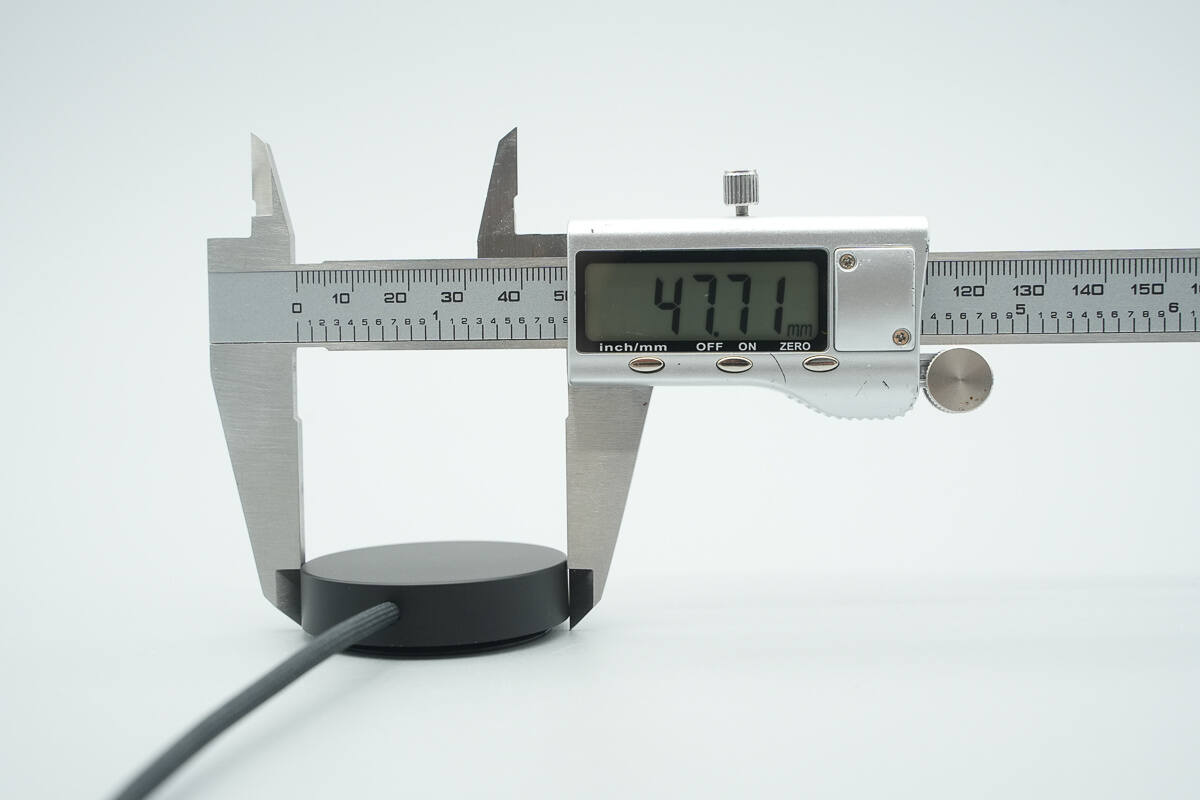

The wireless charging base adopts a disc-shaped design, with the top surface and sides formed as a single integrated housing and finished with a matte texture.

The rubber anti-slip pad on the bottom helps stabilize the unit, while a breathing light ring along the edge indicates the charging status.

Product Name: Wireless Magnetic Charging Base

Model: LFTB02 WC-L

Input: 5V 2A, 9V 2.22A

Output: 15W Max

The length of the cable is about 99.5 cm (39.17 inches).

The diameter of the wireless charging base is 47.71 mm (1.88 inches).

The thickness is about 12.19 mm (0.48 inches).

The two brush heads are stored inside the compartments.

The handle is wrapped in a protective paper layer, and the top output shaft is protected by a plastic casing.

The housing is made of high-transparency PC material with an AF anti-fingerprint coating.

The front features a mode/work indicator light, a pressure-sensitive button, a flight mode indicator light, and a battery/Bluetooth status indicator light.

Close-up of the output shaft.

The pressure-sensitive button features a seamless, integrated design.

Close-up of the mode/work indicator lights: the number of illuminated lights corresponds to the selected level, with white indicating a comfort cleaning mode and orange indicating a deep cleaning mode.

The battery and Bluetooth status indicator at the bottom is also a two-in-one design: green indicates sufficient battery, red indicates low battery, and blue indicates successful Bluetooth connection.

It also supports flight mode, preventing accidental power-on during travel.

The bottom black plastic casing has a matte finish with smoothly rounded edges, and the housing is also printed with product specifications.

Model: LFTB02‑PT

Voltage: 7.6 V

Rated Input Power: 2 W

Battery Capacity: 900 mAh

Waterproof Rating: IPX8

Overview of the toothbrush with the brush head assembled.

The length of the handle is about 142.94 mm (5.63 inches).

The width is about 28.35 mm (1.12 inches).

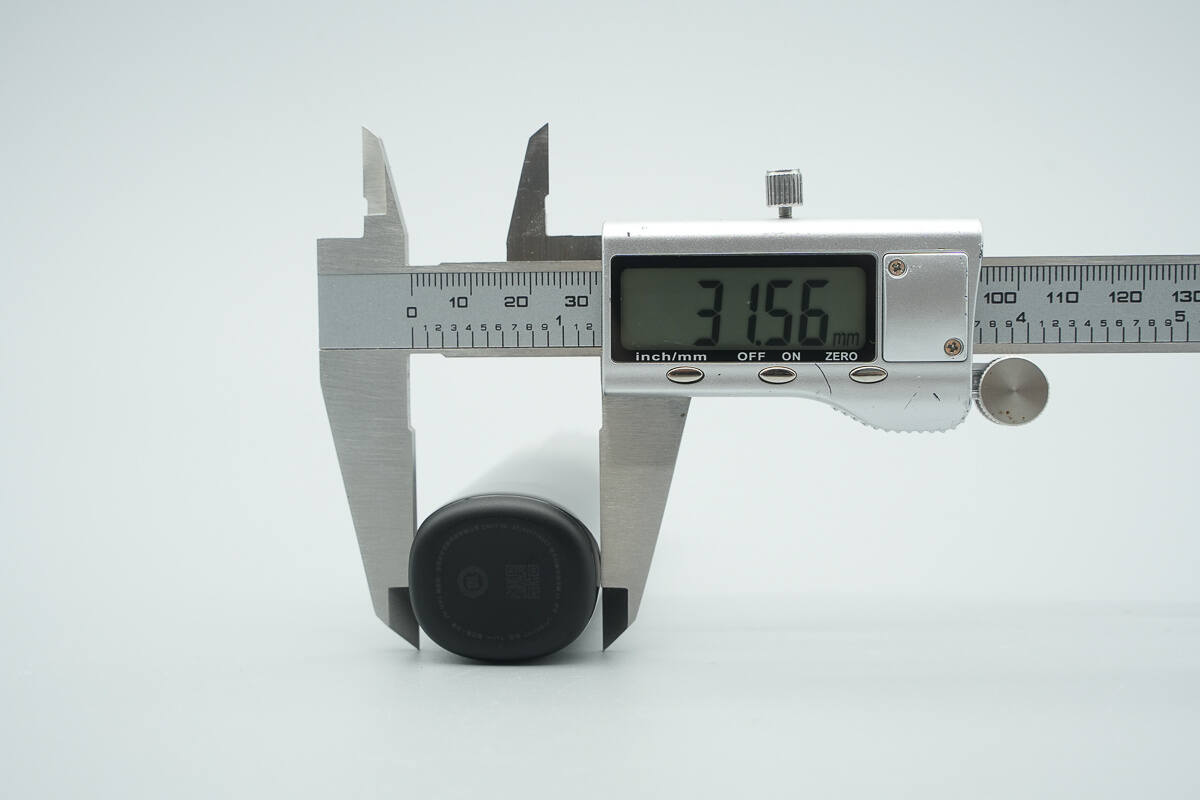

The thickness is about 31.56 mm (1.24 inches).

That's how big it is on the hand.

The weight is about 147 g (5.19 oz).

Both the base and the handle contain magnets, allowing the toothbrush to quickly attach and align during charging while remaining stable.

ChargerLAB POWER-KM003C shows the output power of the charger is about 2.85W.

Teardown

Next, let's take it apart to see its internal components and structure.

Remove the bottom cover. The cover is secured on both sides with clips.

The sides of the bottom cover have a sealing ring, and adhesive is applied inside.

Remove the internal module from the housing.

The wireless charging receiver coil is fully encapsulated in resin and is equipped with a thermistor.

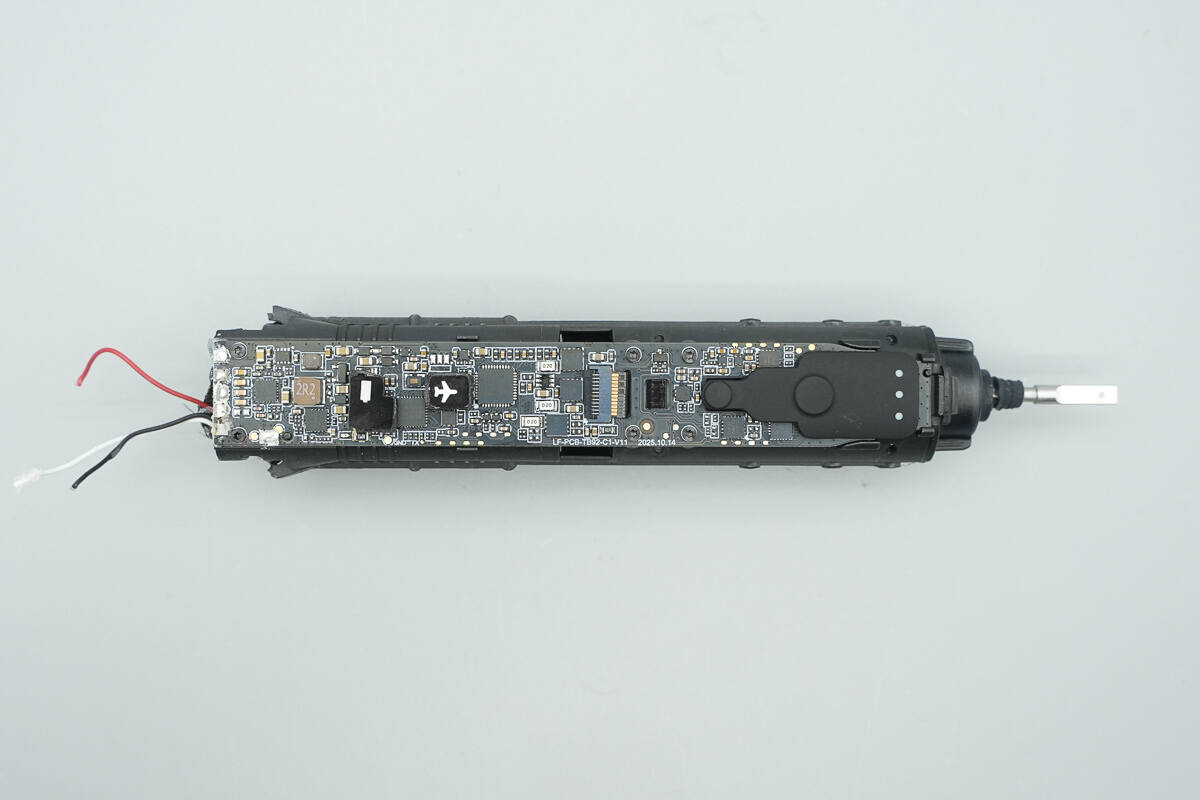

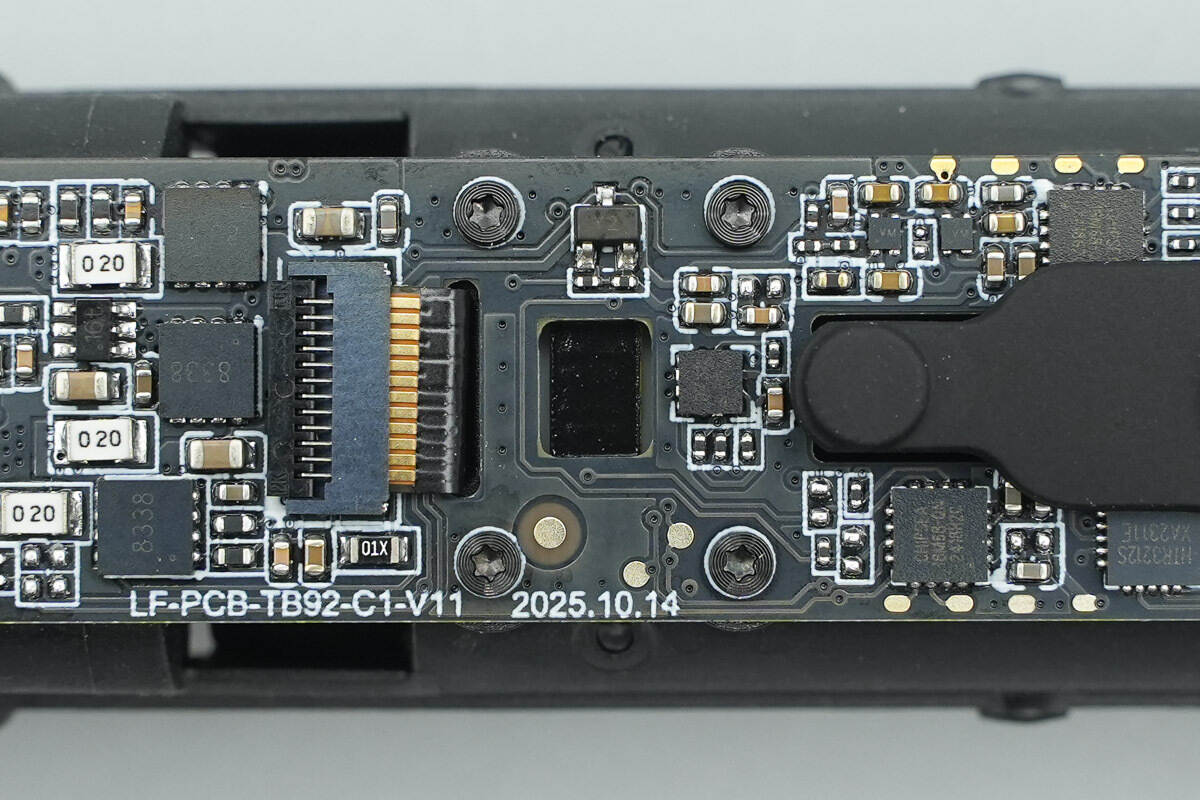

The PCB is installed on the front of the module.

The PCB is secured with screws, and the motor is connected to the PCB via a ribbon cable.

The pressure-sensitive button and mode/work indicator lights are covered by a rubber layer to prevent light leakage.

Rubber pads are placed beneath the light guides for the battery/Bluetooth status indicator and the flight mode indicator.

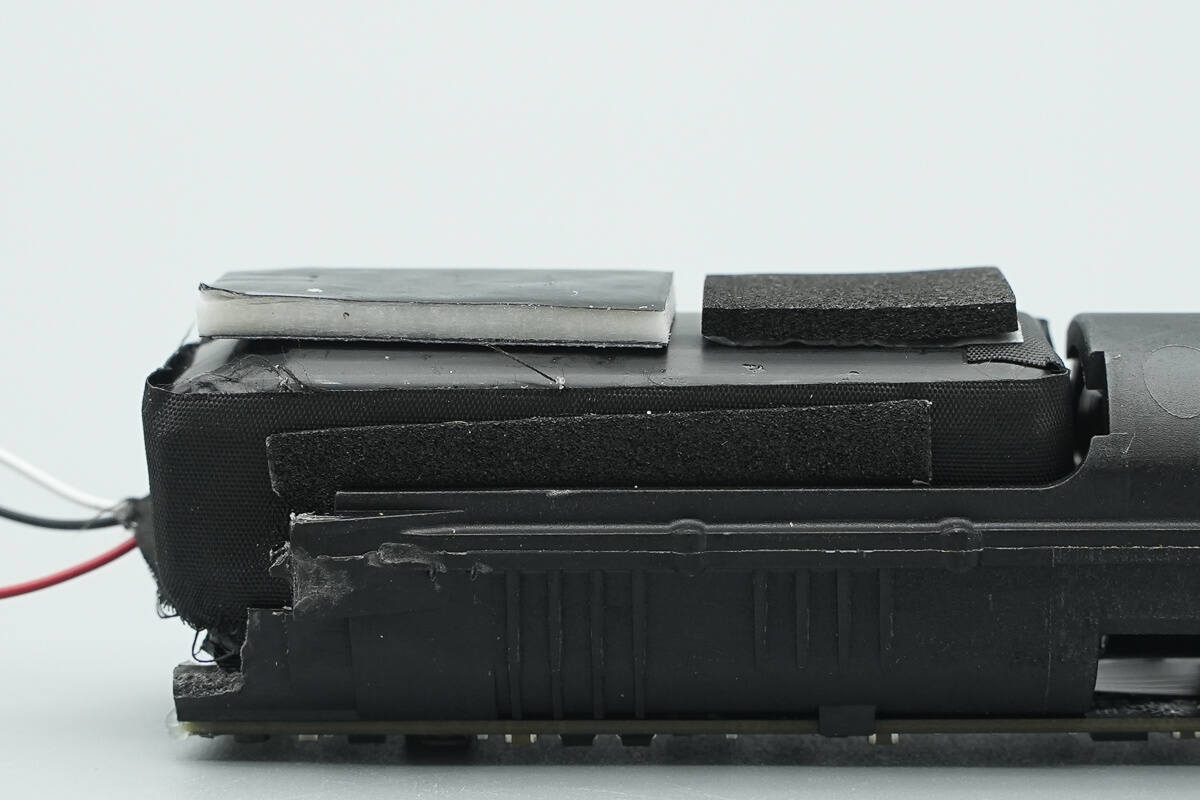

The back of the module houses the battery pack and the motor.

The battery pack is fitted with a cushioning protective pad.

The sides of the module are wrapped with insulating cloth tape and also fitted with protective pads.

The casing around the motor is perforated, allowing part of the information on the motor to be visible.

Completely separate the core components of the module, including the battery pack, motor, and PCB.

The plastic frame is molded as a single piece, and double-sided tape is used to secure the battery pack in place.

The battery pack is wrapped in black insulating plastic, with a parameter sticker affixed to the side.

Model: XD.901850-2S

Nominal Voltage: 7.6Vdc

Charging Limit Voltage: 8.7Vdc

Rated Capacity: 900mAh

Rated Energy: 6.84Wh

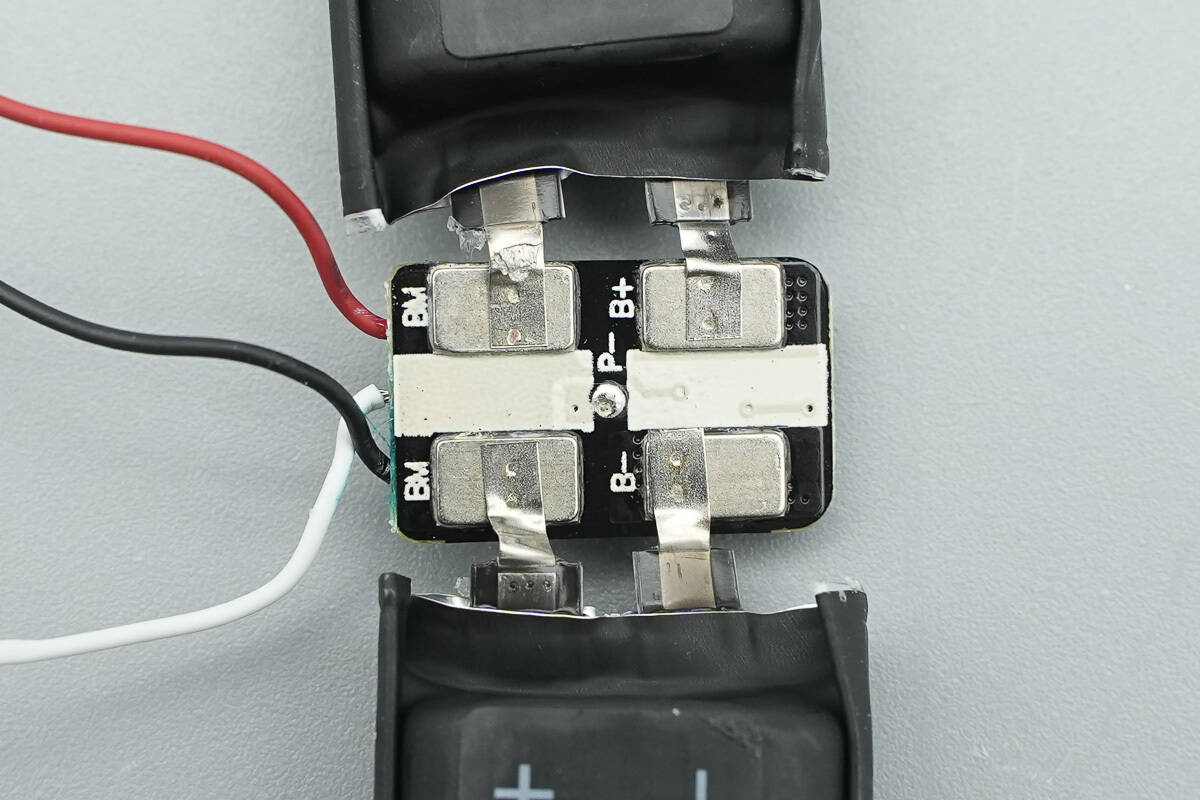

The battery pack consists of two polymer battery cells and is equipped with a battery protection PCB. Foam is placed between the tabs of the battery cells.

The two battery cells are spot-welded to the PCB using nickel strips.

Separate the battery cells from the PCB.

The two battery cells are identical, model XD901847, with a specification of 900mAh/3.42Wh/3.8V, and the manufacturing date is October 16, 2025.

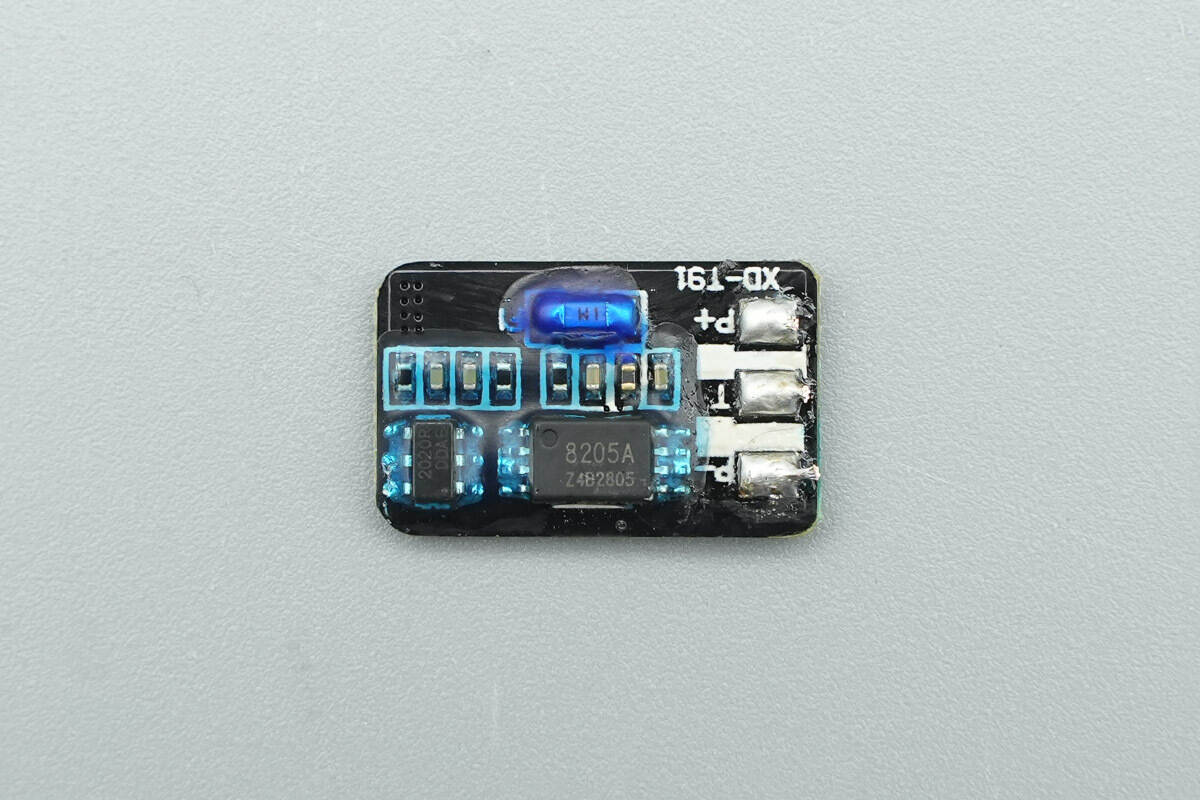

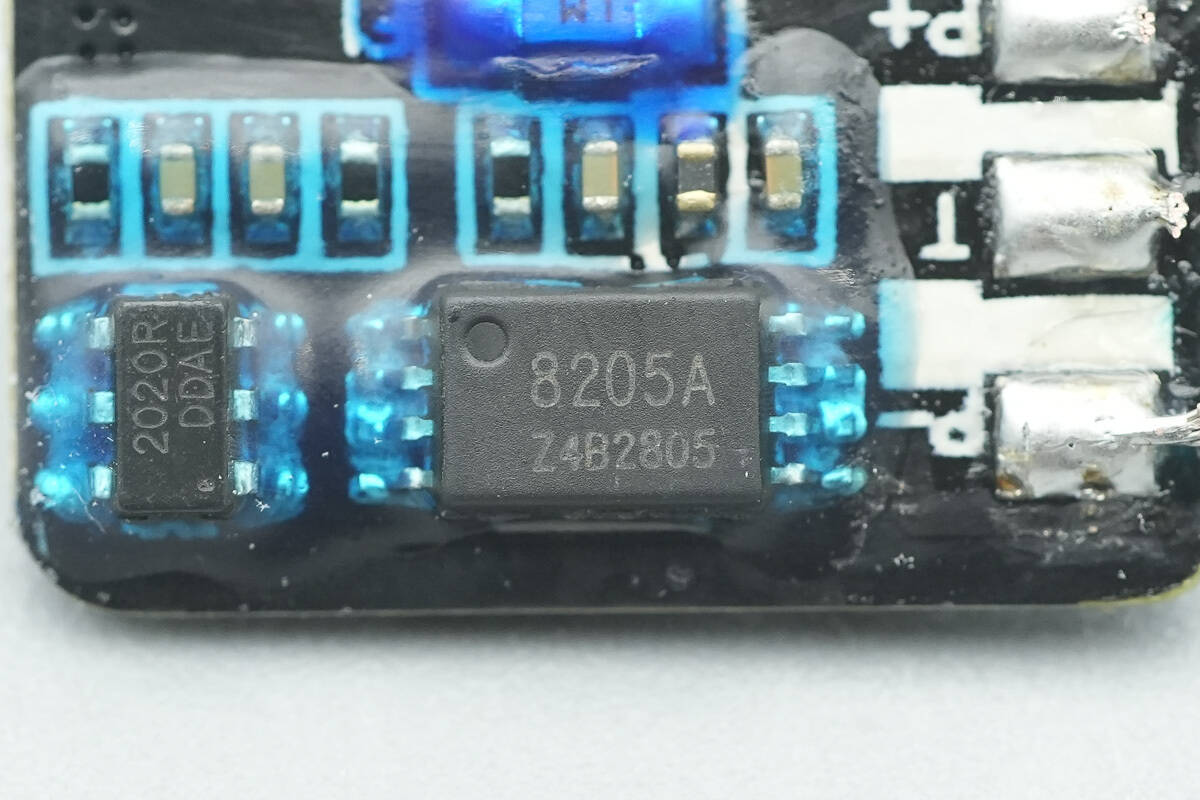

The front of the battery protection PCB contains components such as a battery protection chip, a battery protection MOSFET, and a fuse.

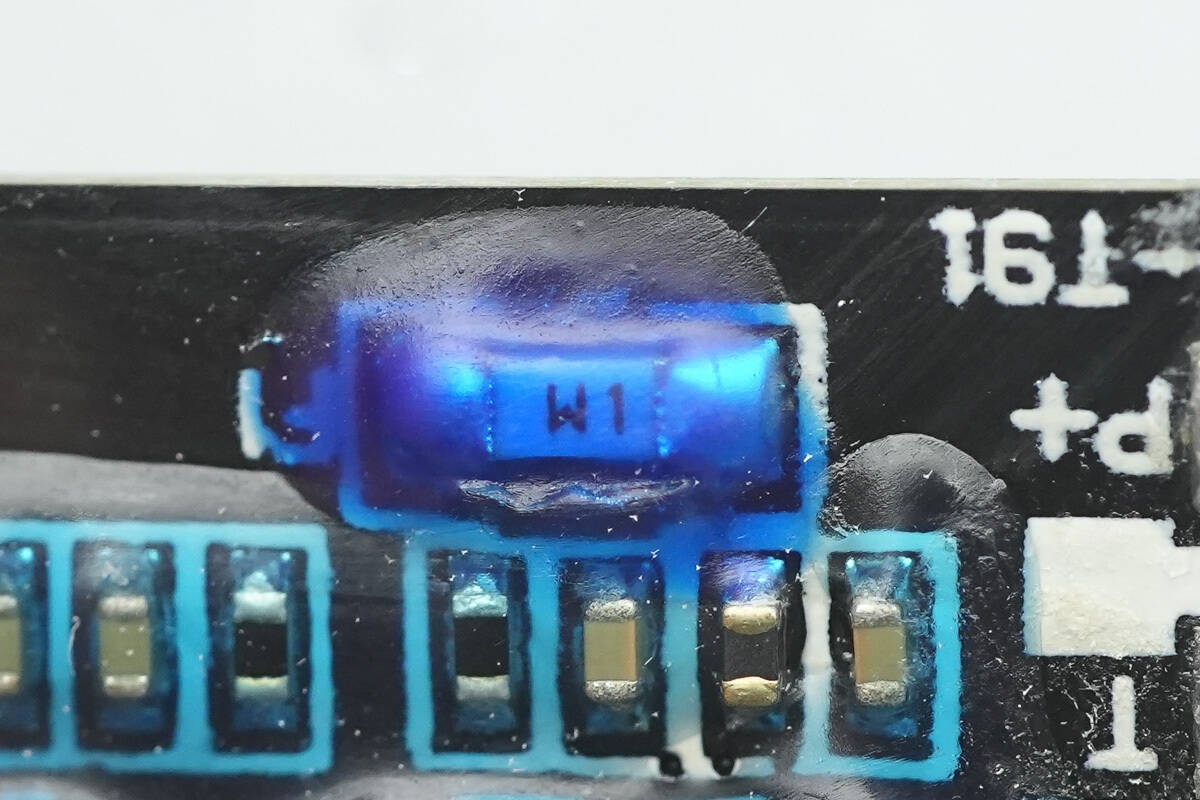

Close-up of the SMD fuse.

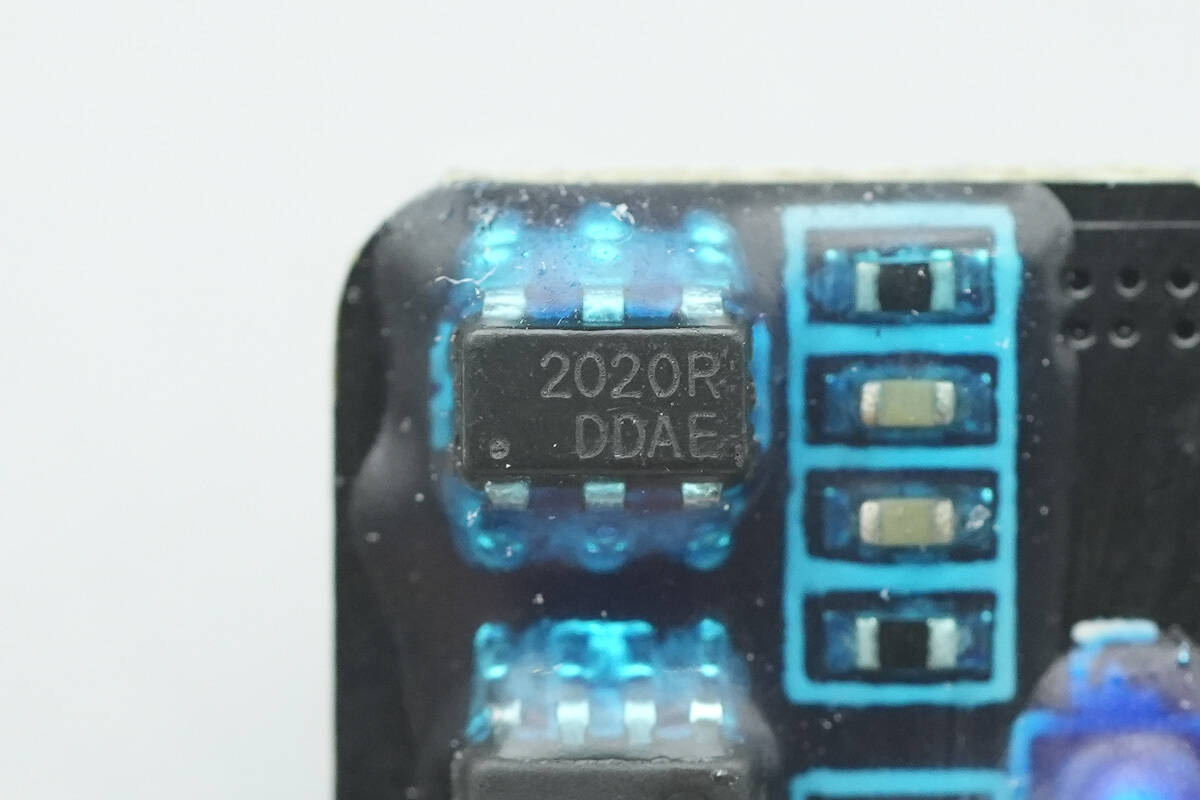

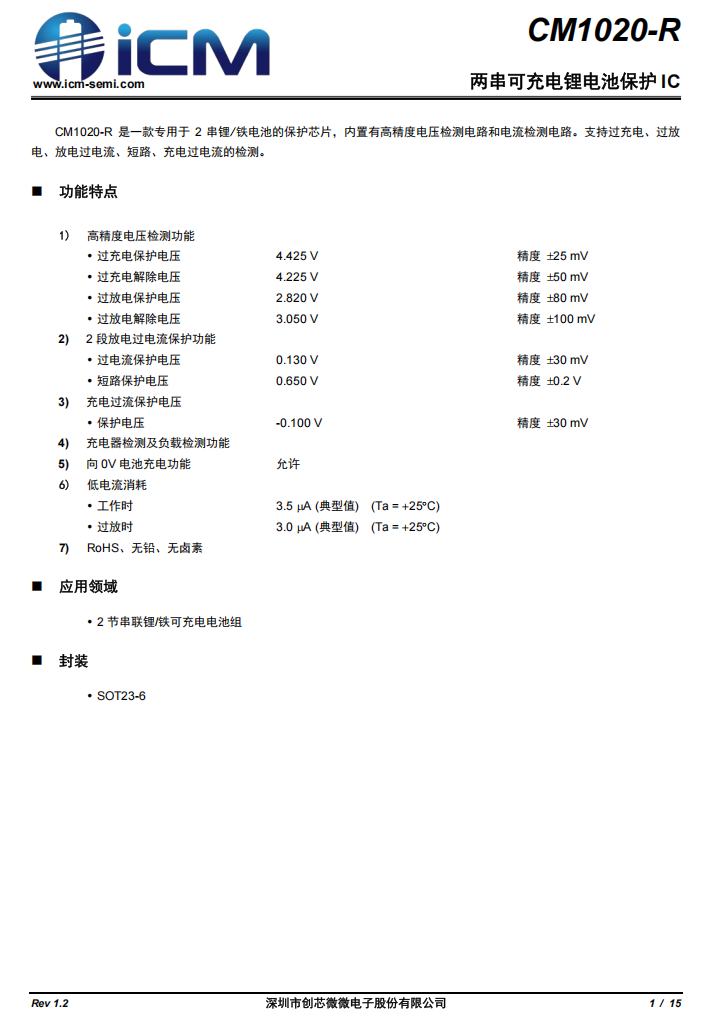

The battery protection chip is from iCM, marked with 2020R, and the model is CM1020-R. This is a protection chip specifically designed for 2-series lithium/iron batteries. It integrates high-precision voltage and current detection circuits, supporting detection for overcharging, over-discharging, discharge overcurrent, short circuits, and charging overcurrent. The chip is packaged in an SOT23-6 form factor.

Here is the information about iCM CM1020-R.

The battery protection MOSFET is marked with 8205A and uses a TSSOP-8 package.

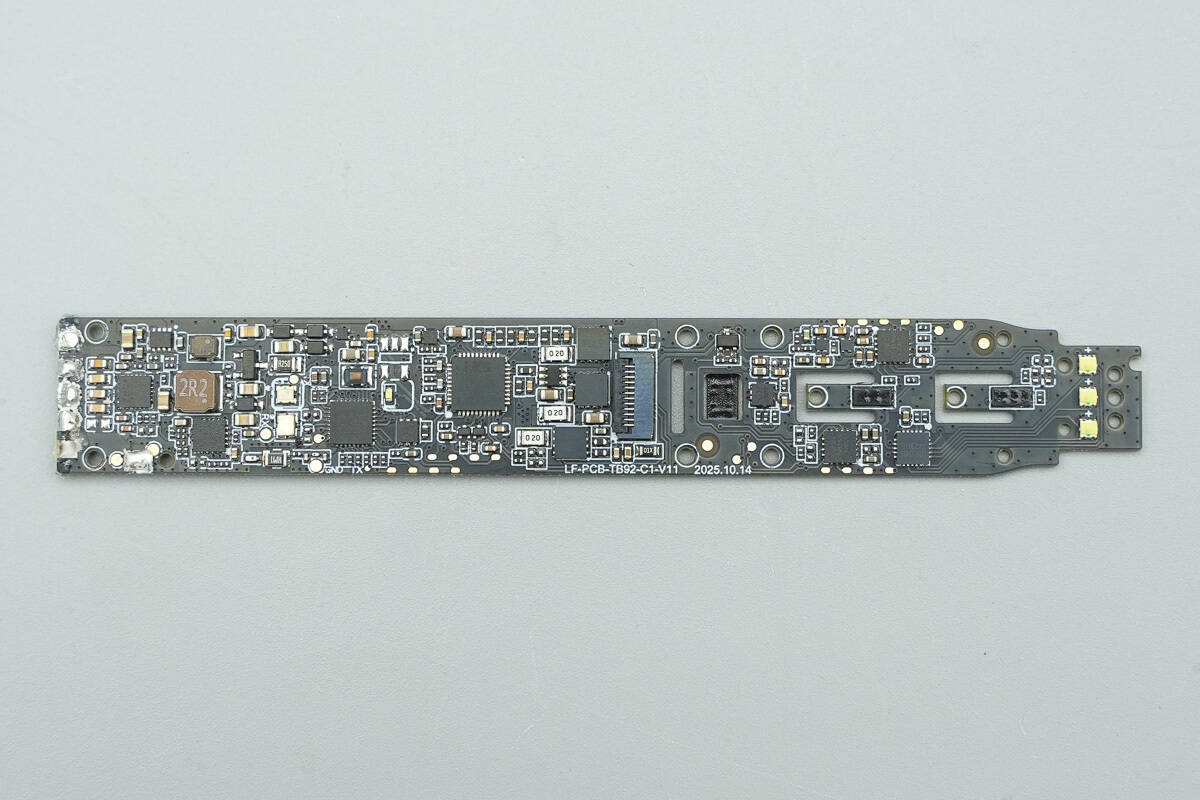

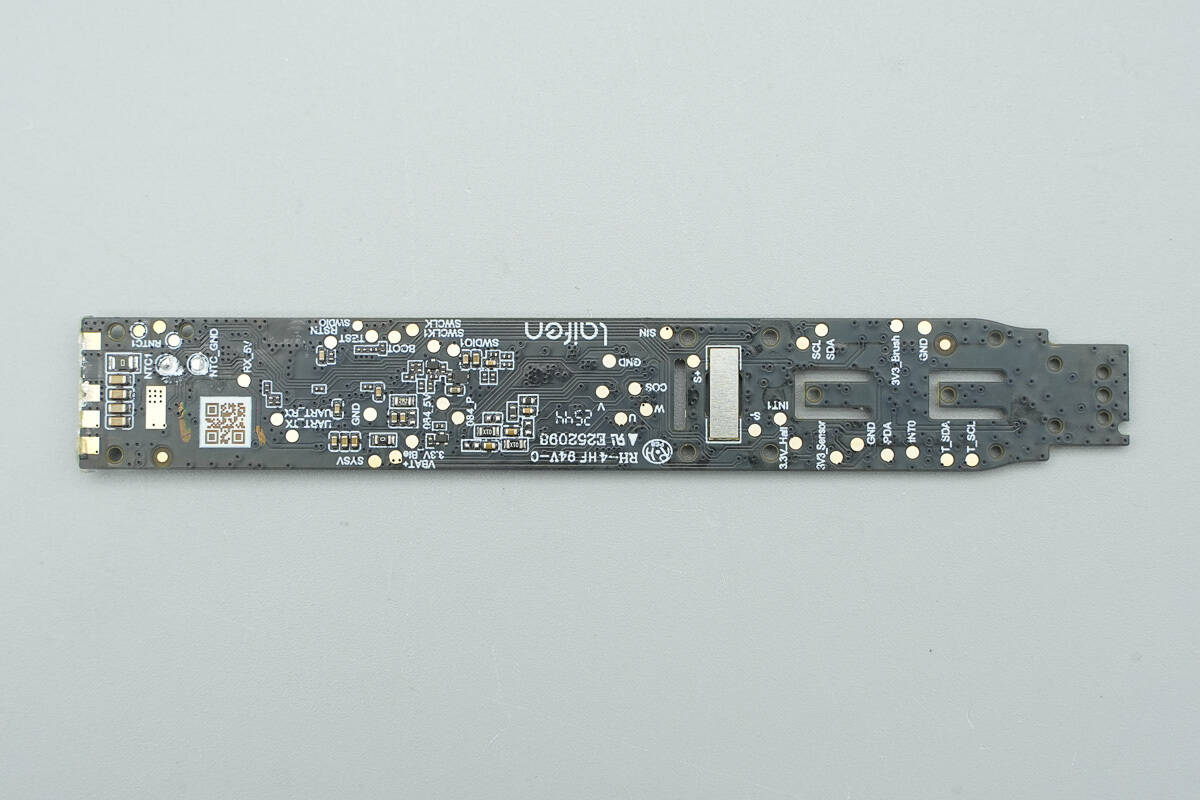

The front of the PCB features components such as a wireless charging receiver chip, a charging management chip, a buck converter chip, a Bluetooth chip, an MCU, a pressure detection chip, an LED driver chip, and a motor driver MOSFET.

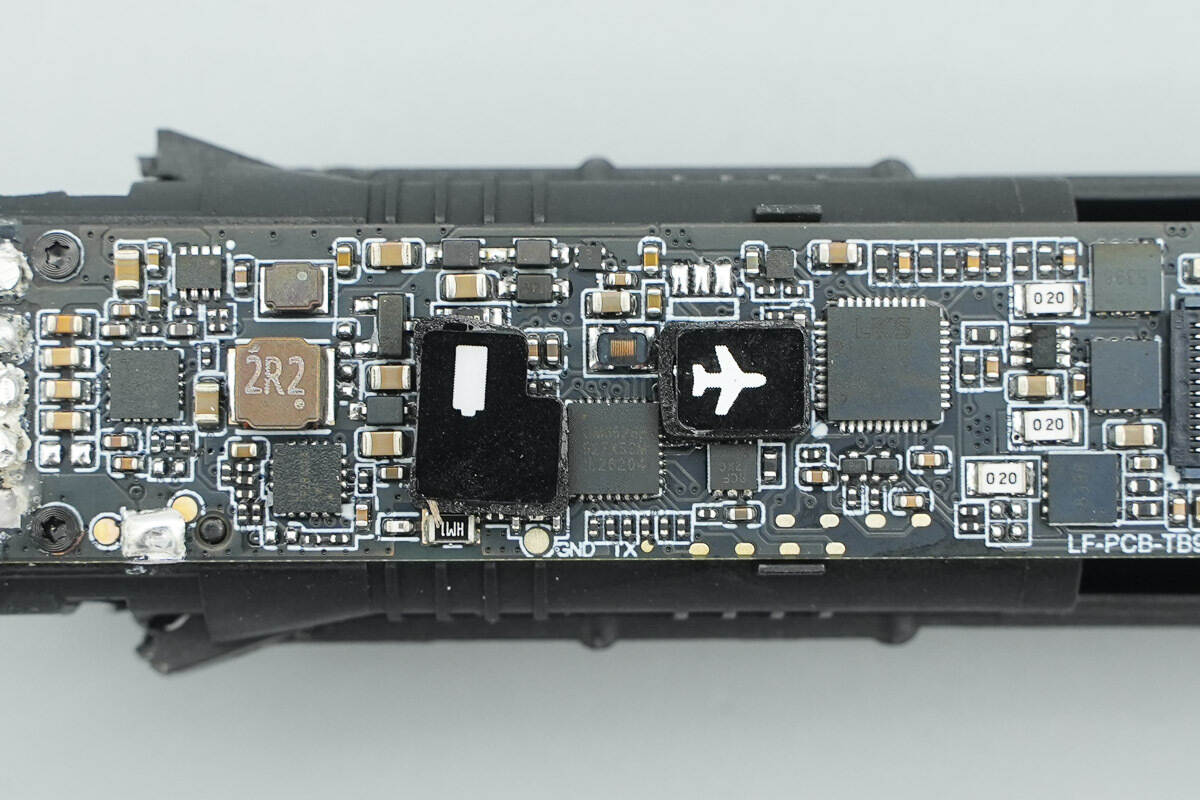

The back of the PCB contains small components such as capacitors, resistors, and other discrete parts.

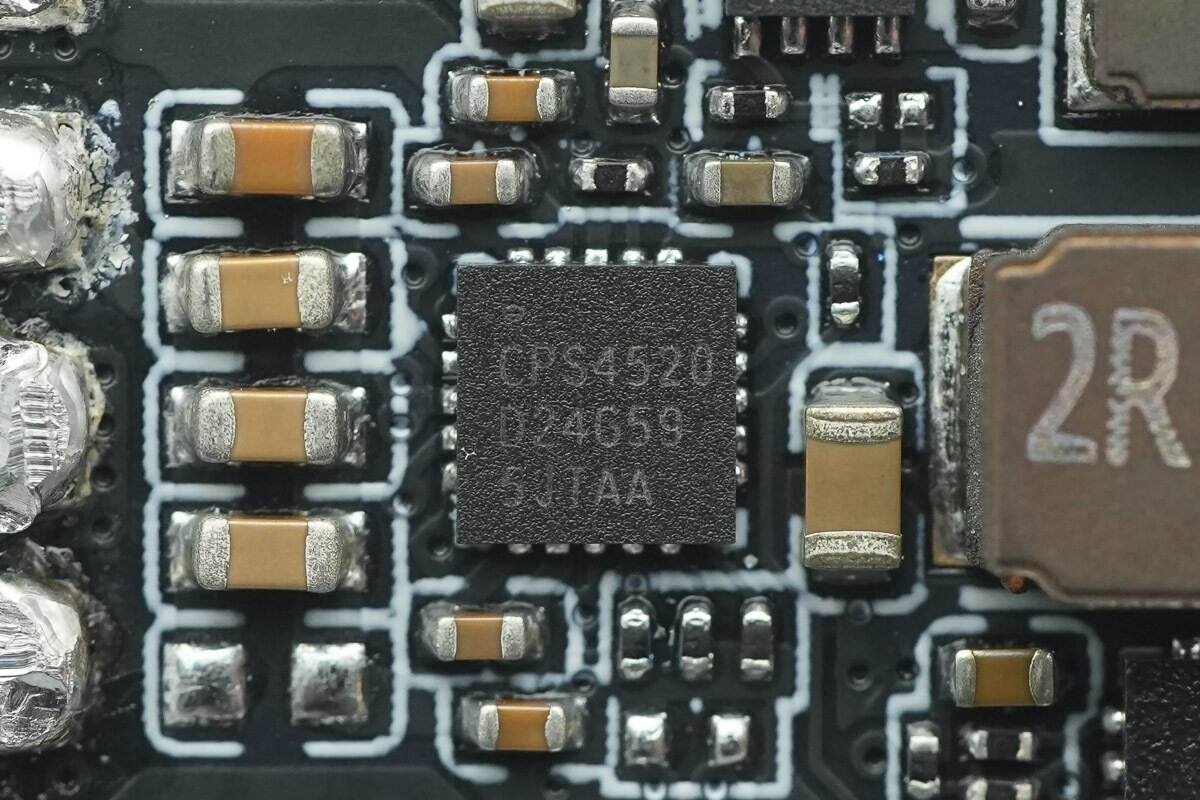

The CPS CPS4520 is a highly integrated wireless charging Rx chip. It supports efficient AC/DC voltage regulation, RxTx communication, and I2C interface communication with the MCU, along with reliable overvoltage, overcurrent, and temperature protection solutions. It uses a compact QFN-20 package, measuring just 3mm x 3mm, and complies with RoHS, halogen-free, and lead-free environmental standards. This makes it ideal for portable electronic devices that have strict space and energy efficiency requirements.

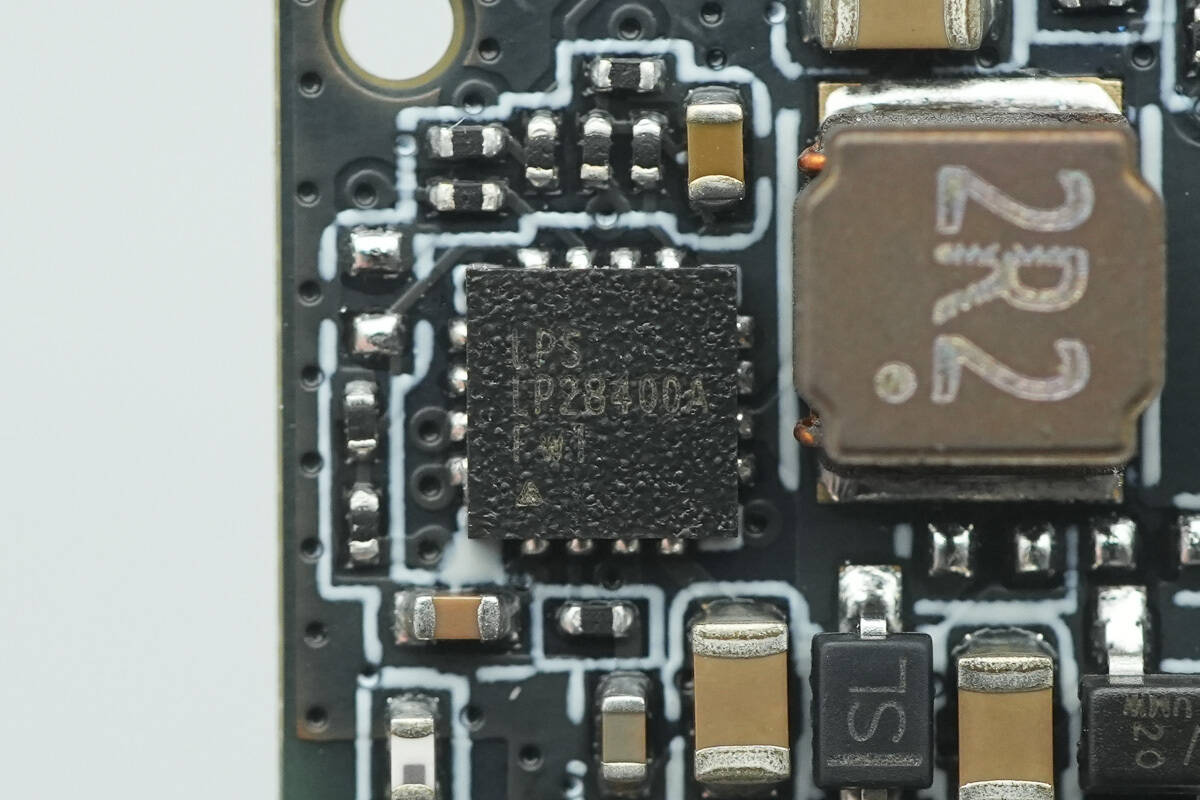

The charging management chip is from LPSemi, model LP28400A. It is a complete constant current/constant voltage switch-mode charger, specifically designed for multi-cell lithium-ion battery packs. It integrates a boost converter and a linear charger architecture, working alongside a USB 2.0-compliant power management IC to enable efficient charging of two lithium-ion cells.

The chip also integrates several practical features, including charging current monitoring, input undervoltage lockout, automatic recharge control, and a status indicator pin to signal the end of the charging cycle.

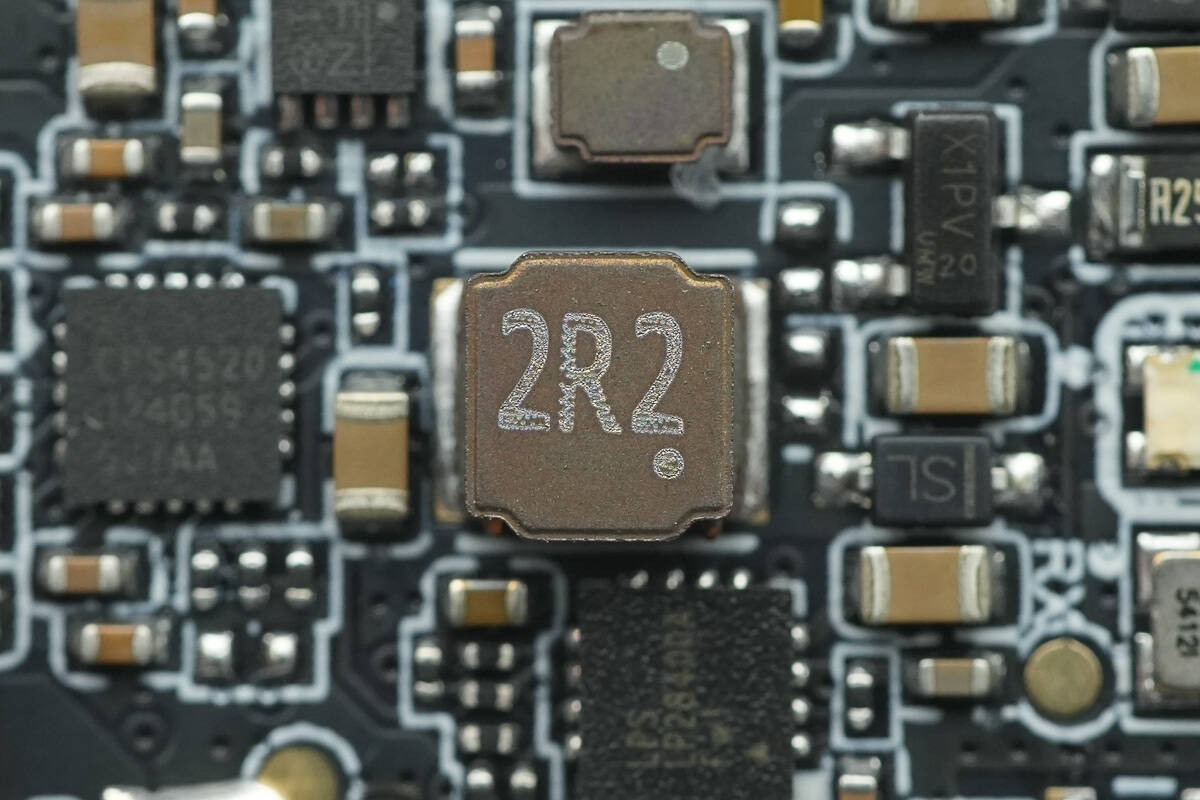

Close-up of the 2.2μH boost inductor.

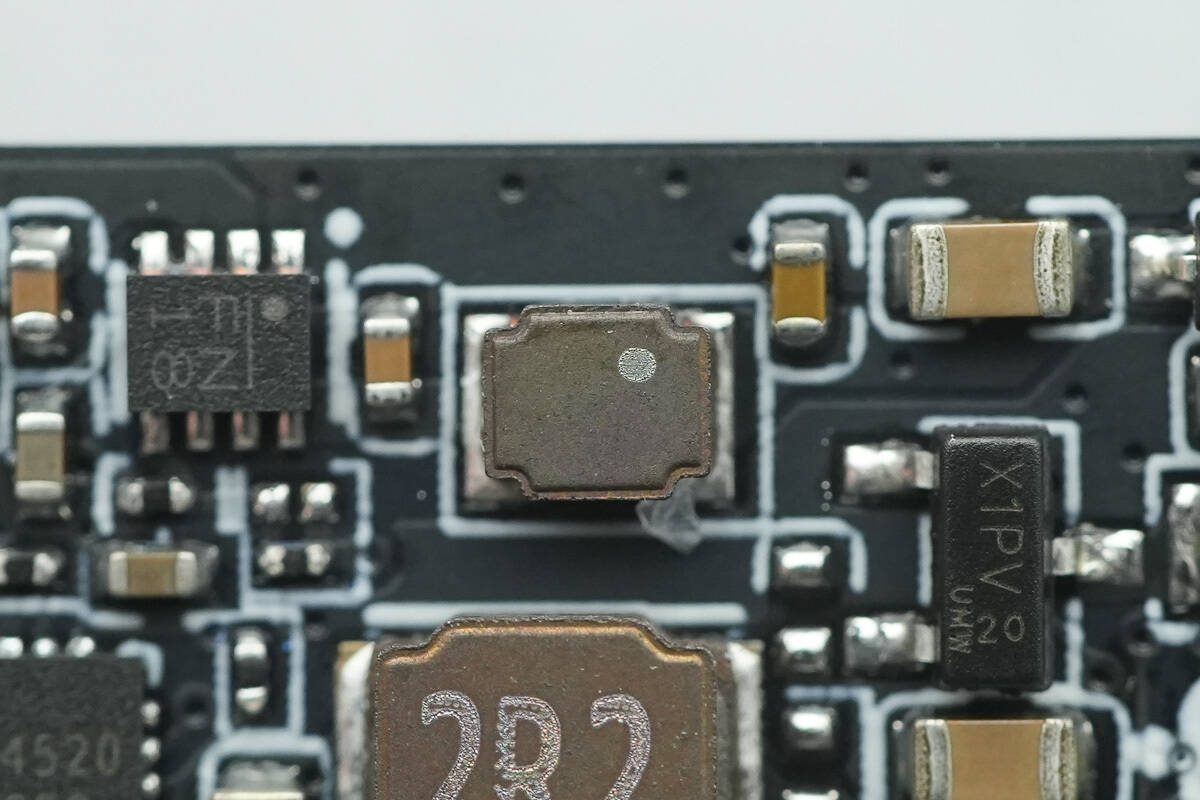

The buck converter chip used for voltage regulation is from MPS, marked with FN, model MP2322. It features an integrated MOSFET, provides an output current of 1A, and comes in a QFN-8 package.

Close-up of the paired buck inductor.

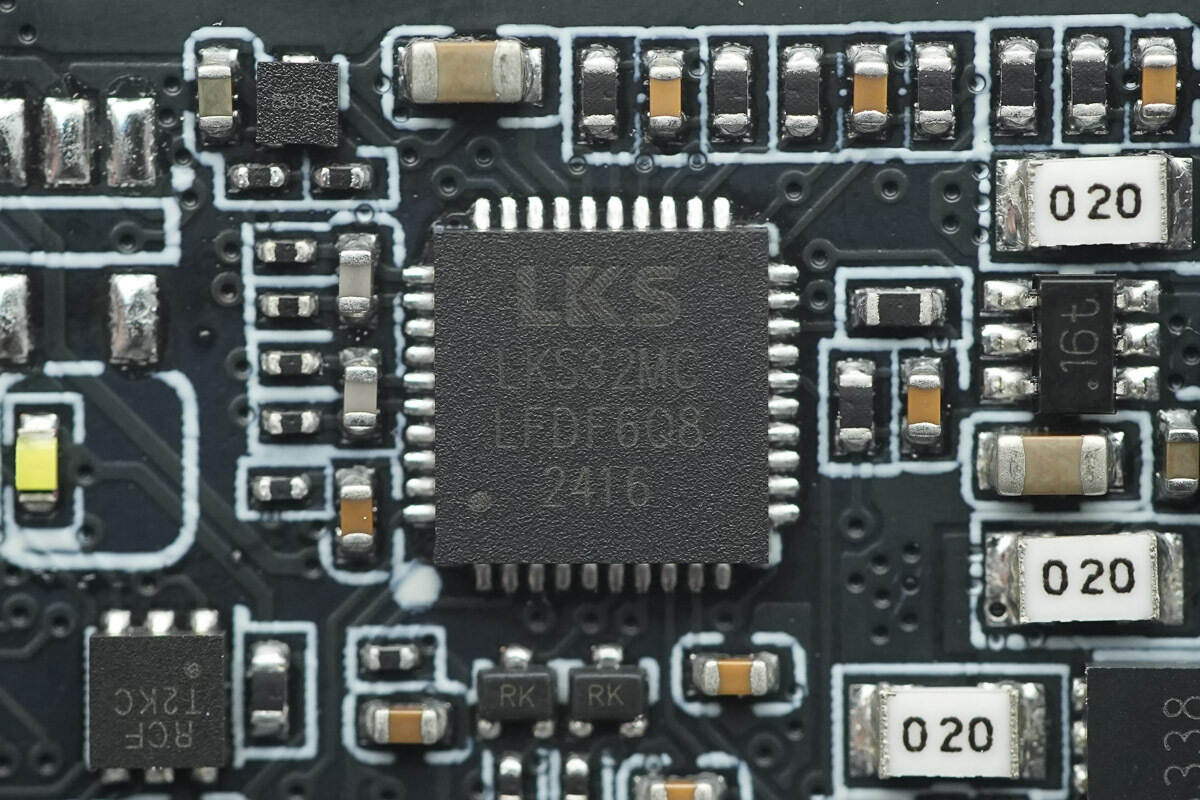

The MCU is from LINKOSEMI, model LKS32MC084DF6Q8. It integrates a 96MHz clock speed, a 32-bit Cortex-M0 core, and a motor control-specific DSP with a custom instruction set. It also features a three-phase full-bridge bootstrap gate driver, capable of directly driving six NMOS transistors for three-phase brushless motor control.

The SGMICRO SGM821 is an ultra-low-power, programmable watchdog timer, specifically designed for system wake-up in duty-cycle operation and battery-powered applications. This device integrates a programmable interrupt timer, with a typical system current of only 35nA. It allows the system to enter sleep mode to reduce power consumption, returning to active mode only when an interrupt is received. Compared to microcontrollers that typically consume microamp-level system current, the SGM821 is particularly well-suited for wireless sensing or other applications that use small batteries.

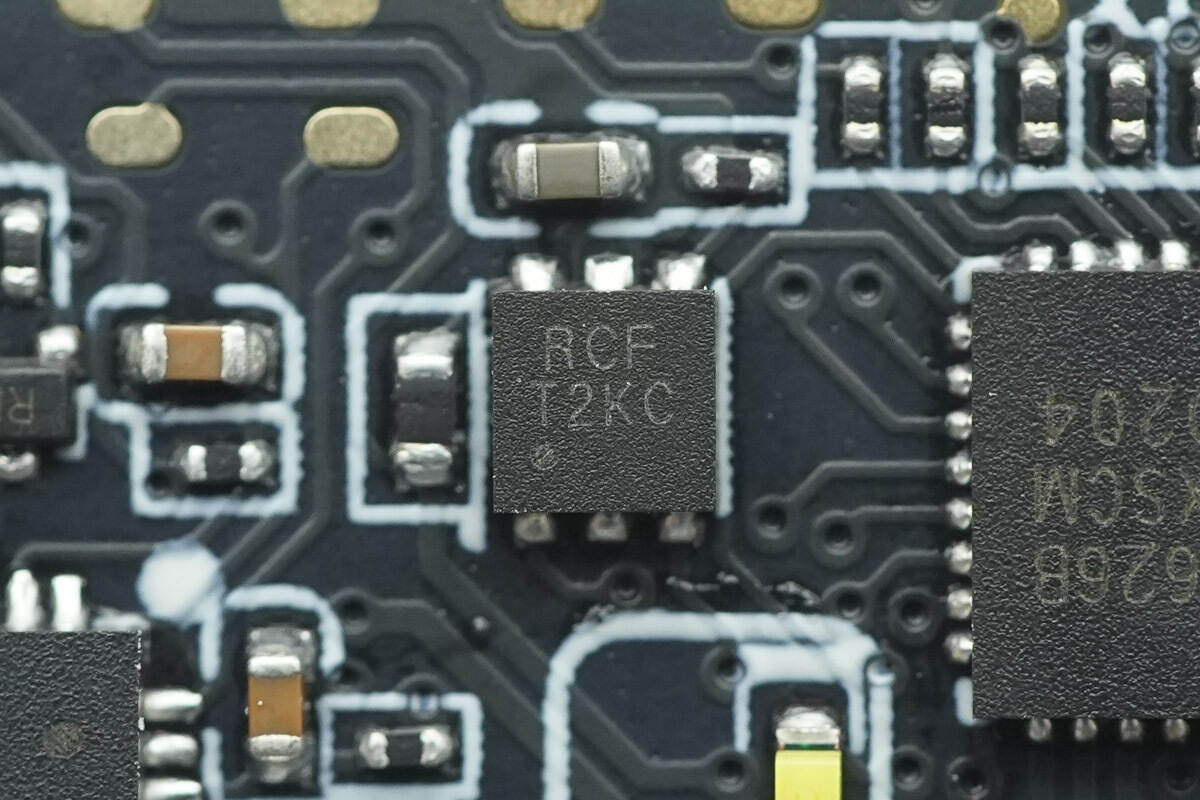

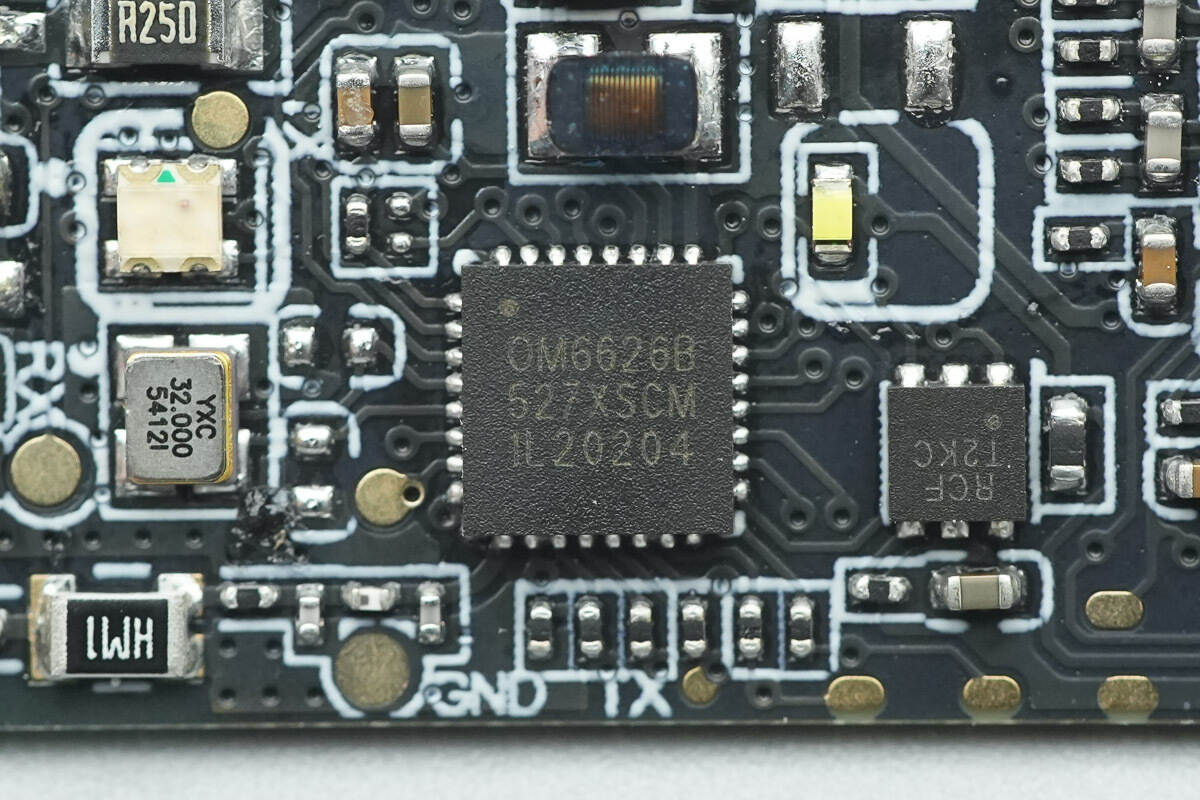

The Bluetooth chip is from OnMicro, model OM6626B. It is a BLE & 2.4G dual-mode SoC that supports Bluetooth 5.4 protocol and is backward compatible. It features a 64MHz Cortex-M4 core and storage resources that include 1MB of Flash and 80KB of SRAM.

The OM6626B is highly favored in the BLE product applications and markets due to its excellent RF performance (transmit power up to +8dBm, and receive sensitivity of -98dBm at 1M rate) and power efficiency (typical TRX currents of 4.2mA and 3.4mA).

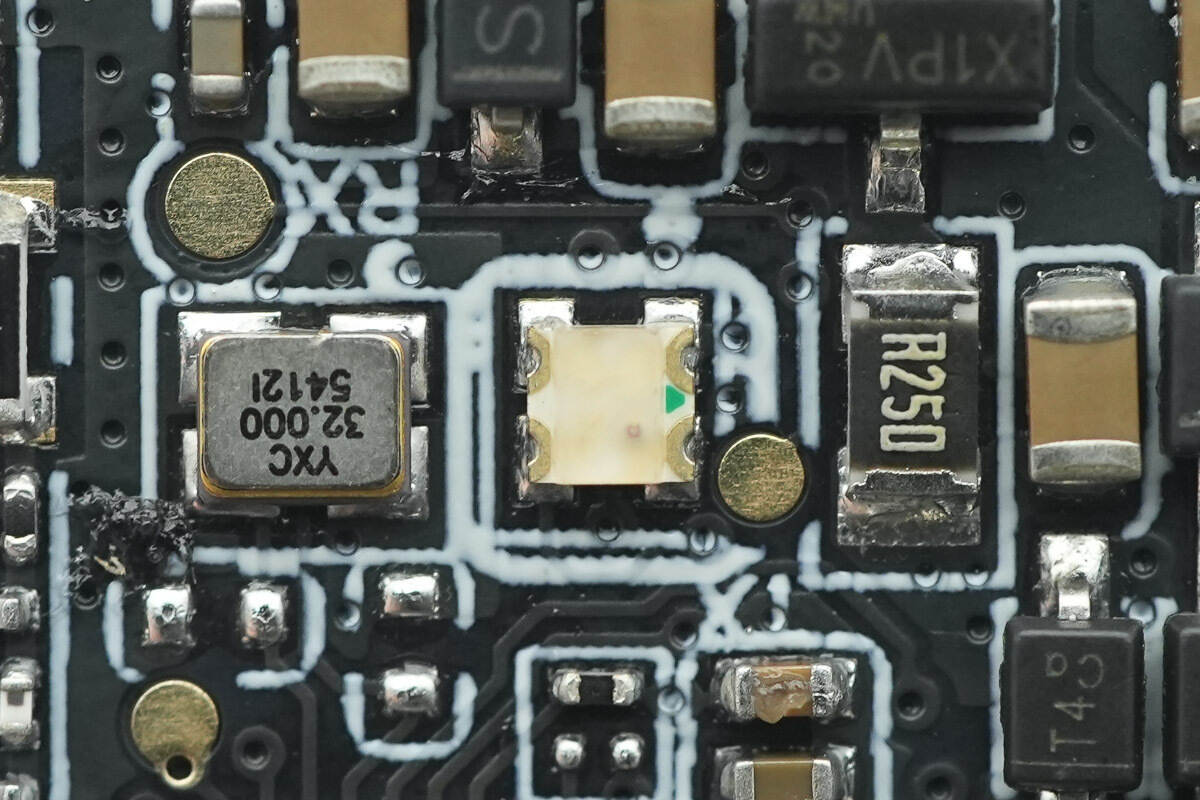

Close-up of the external 32.000MHz crystal oscillator.

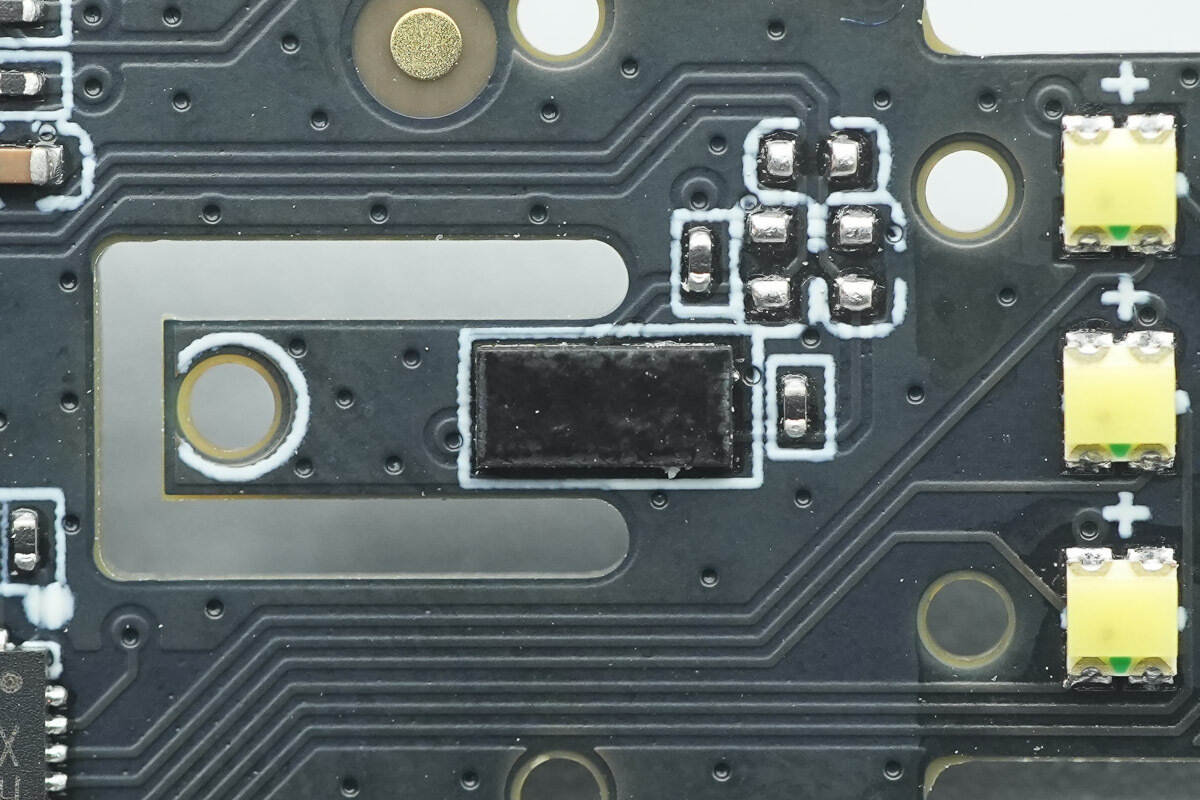

Close-up of the battery/Bluetooth status indicator light.

Close-up of the flight mode indicator light.

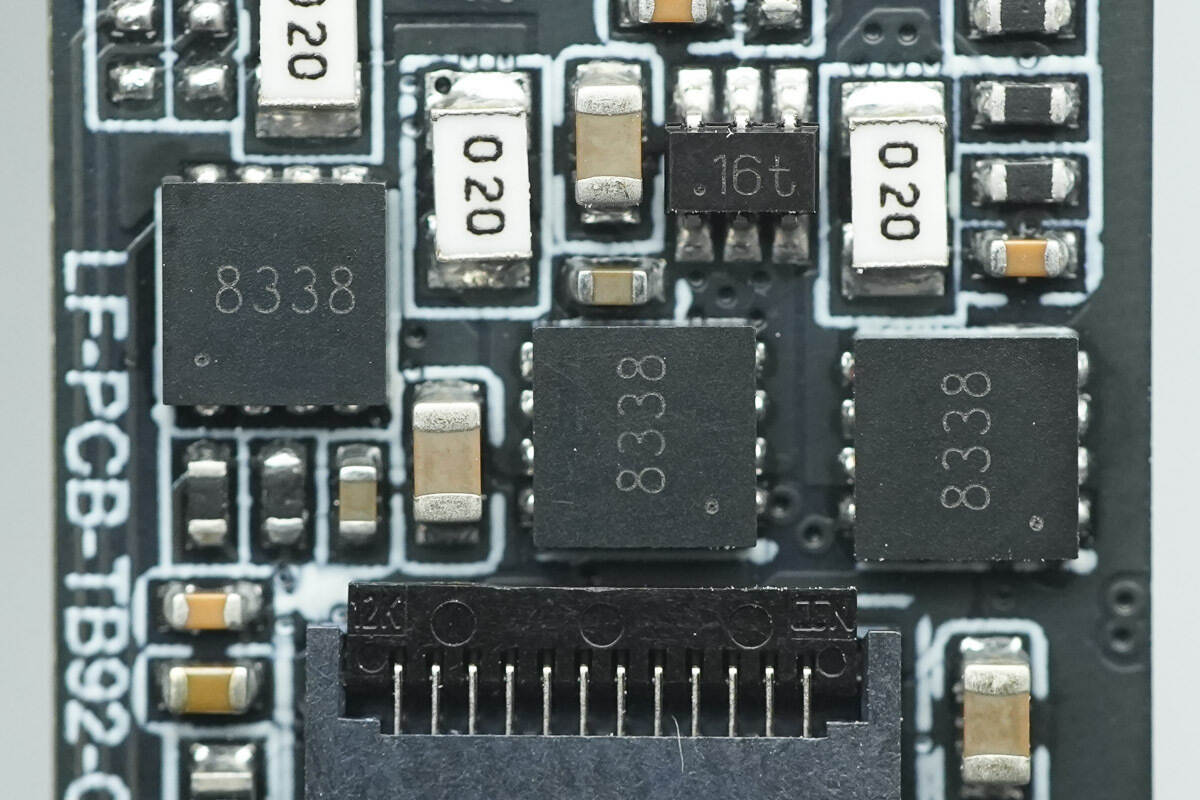

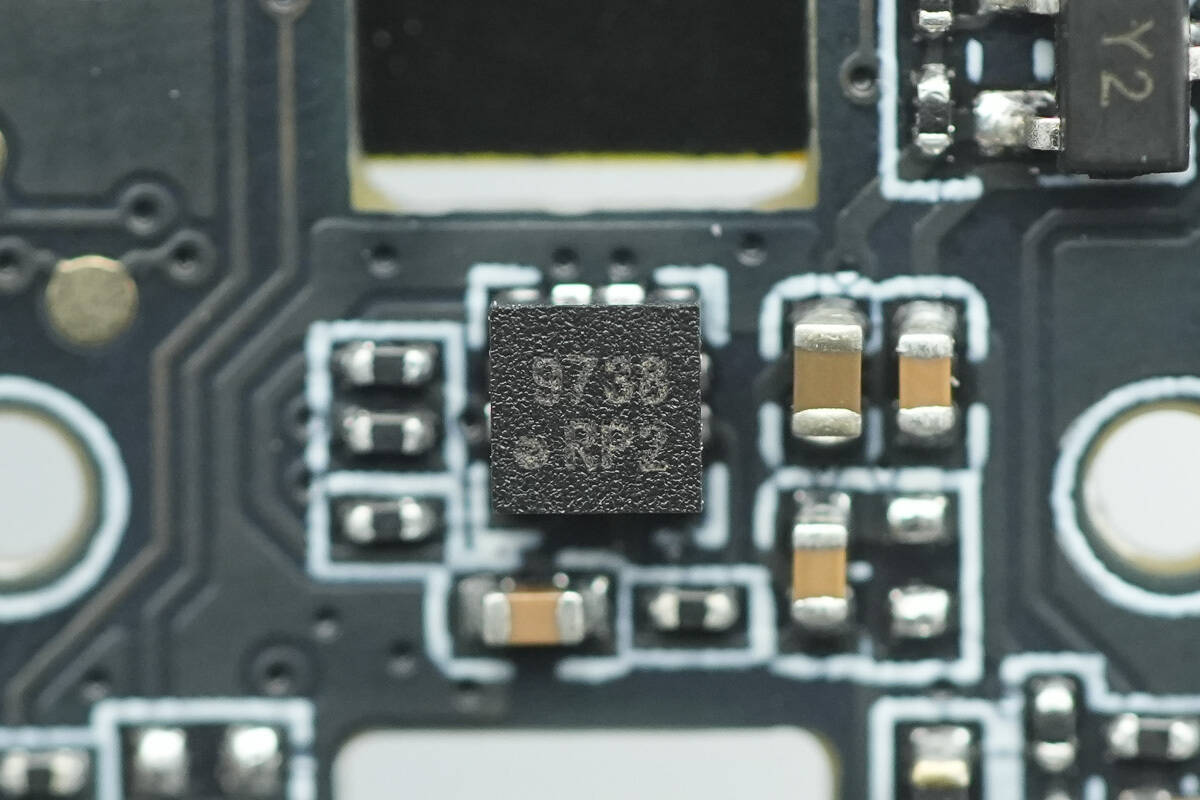

The three MOSFETs used to drive the servo motor are marked with 8338 and come in a DFN 3x3 package.

The accelerometer chip is used for the pick-up wake-up function.

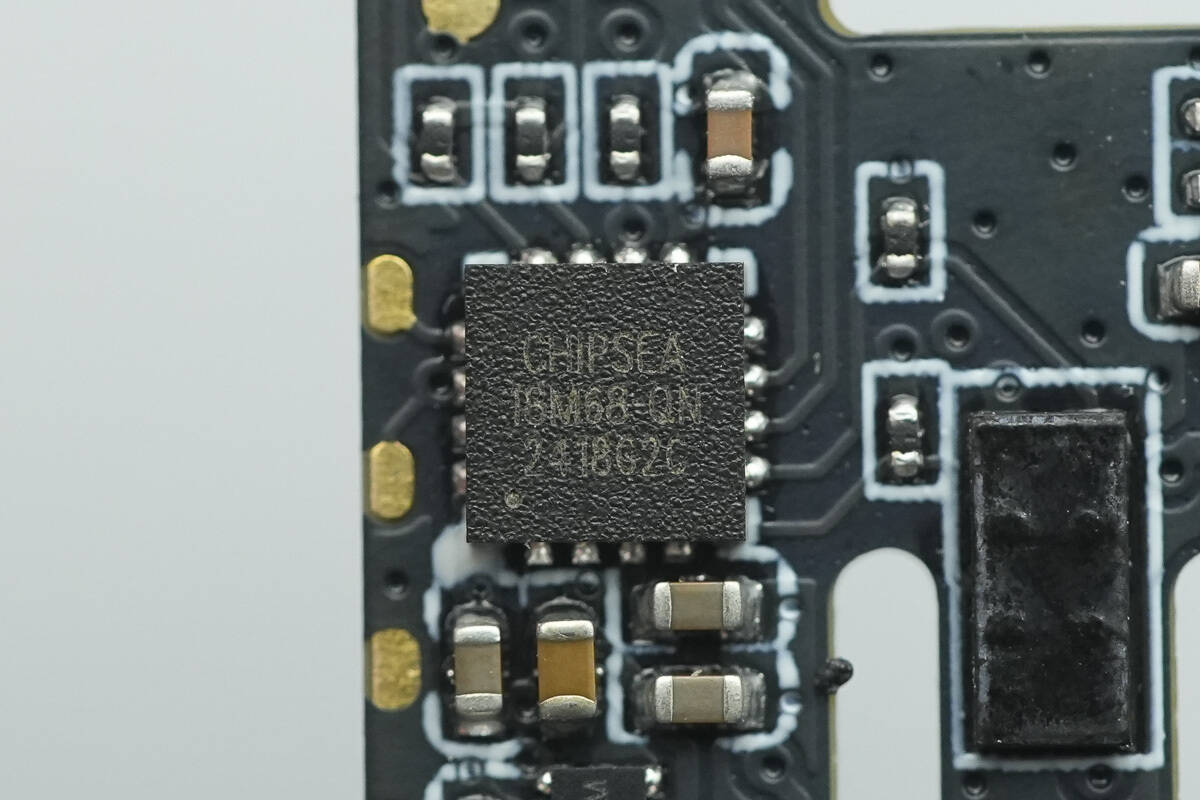

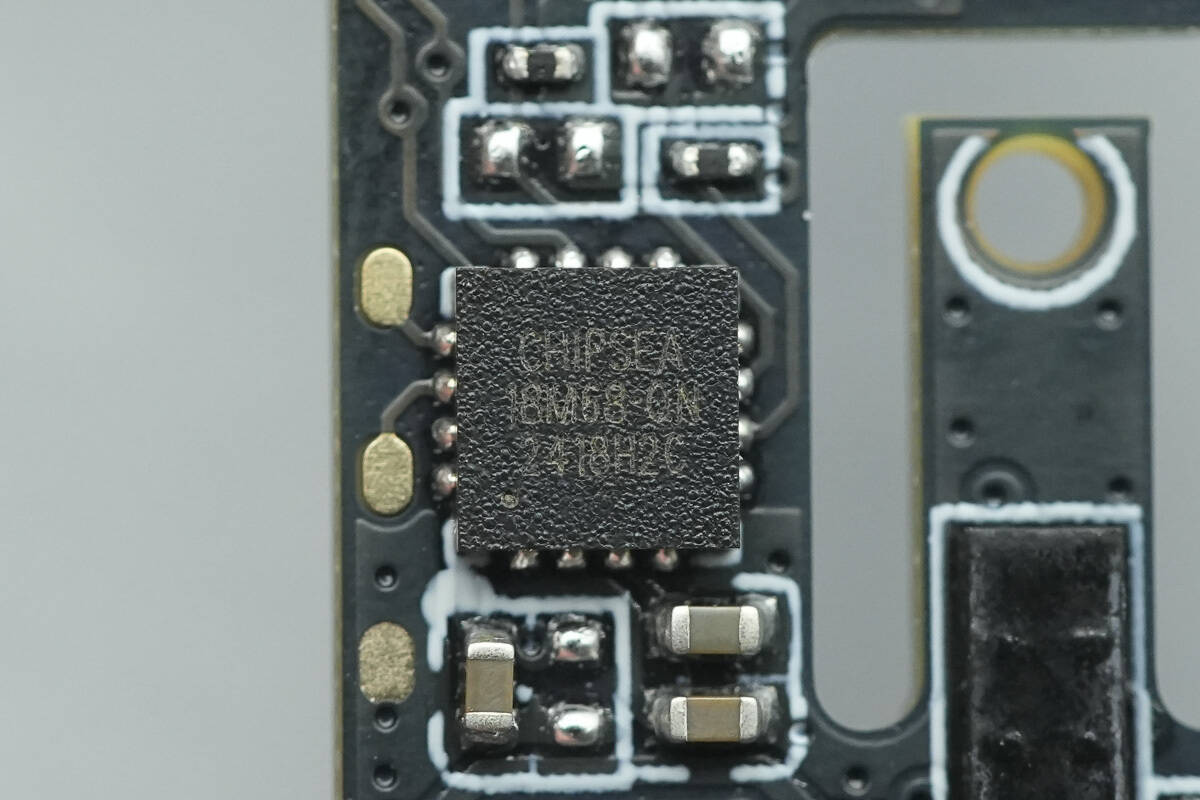

The pressure sensor chip is from Chipsea, model CSU18M68. It supports both analog front-end mode and MCU mode of operation. The chip features dual-channel pressure sensing, a built-in 16-bit ADC, a temperature sensor, and an I2C interface. It is suitable for applications in smartphones, wearable devices, laptops, and industrial applications. The chip is packaged in a QFN16 form factor.

Another Chipsea CSU18M68 is used for detecting brushing pressure, enabling precise triggering and timely feedback reminders.

Close-up of the pressure sensor.

The LED driver chip is from Heroic, model HTR3212S. It is a 12-channel LED PWM driver with a fixed PWM frequency of either 3kHz or 22kHz. The maximum output current for each channel can be adjusted through an external resistor, with a maximum of 38mA, and each channel can be independently controlled with 4 selectable brightness levels. The brightness of each channel can be finely tuned with 256 levels through I2C control. It comes in a QFN-20L package.

Close-up of the mode/work indicator light.

Laifen's self-developed servo motor supports a vibration frequency of up to 66,000 movements per minute and a 360° rotating shaft angle. It provides powerful cleaning performance, significantly enhancing the effectiveness of teeth cleaning.

The motor is marked with "Laifen," "Servo System," and "360° | 66000Hz."

The rear of the motor features a welded coil and a connecting ribbon cable, with the Laifen logo at the center.

Well, those are all components of the Laifen i2 Sweeping & Vibrating Electric Toothbrush.

Summary of ChargerLAB

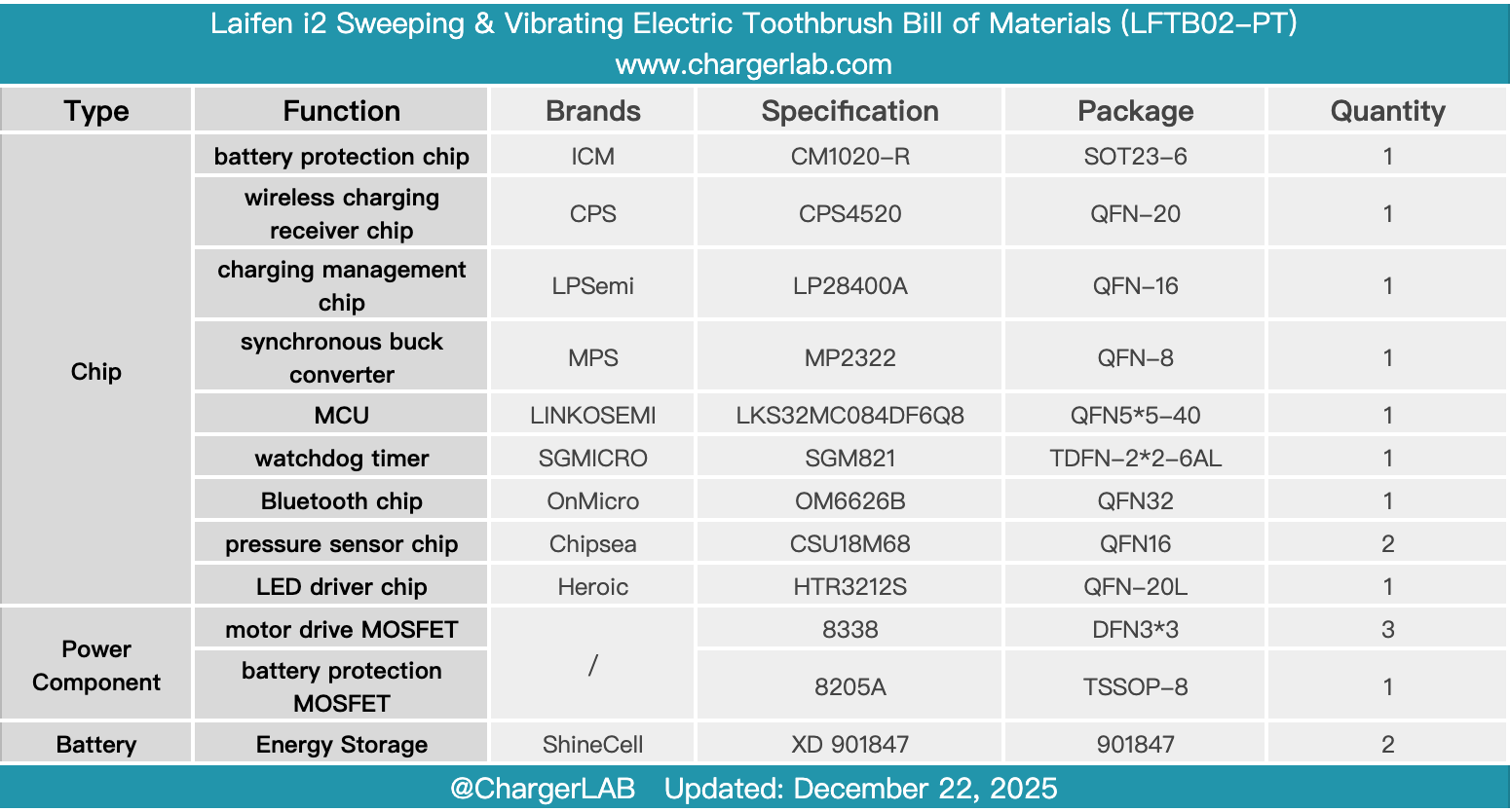

Here is the component list of the Laifen i2 Sweeping & Vibrating Electric Toothbrush for your convenience.

Laifen's new-generation sweeping & vibrating electric toothbrush i2 is available in three versions: ABS, transparent, and aluminum alloy. It features a brand-new magnetic wireless charging system, offering convenience, stability, and resistance to moisture. The toothbrush supports Bluetooth connectivity with a mobile app for personalized settings and includes various user-friendly features, greatly enhancing the overall user experience. The design is highly thoughtful and focused on user needs.

After taking it apart, we found that the battery pack is from ShineCell and is a high-voltage lithium battery. It uses the CPS wireless charging receiver chip, CPS4520, and employs the iCM CM1020-R lithium battery protection solution to ensure protection during the battery charging and discharging process.

The handle houses the LINKOSEMI LKS32MC084DF6Q8 MCU, which is used for servo motor control. The OnMicro OM6626B is used for Bluetooth connectivity, while the Chipsea CSU18M68 handles button control and pressure detection during the brushing process. The Heroic HTR3212S is responsible for controlling the indicator lights, and an accelerometer sensor is included to enable the pick-up wake-up function.

Related Articles:

1. Teardown of Baseus PicoGo AH11 140W GaN Fast Charger (E01207)

2. Teardown of GreatWall 3000W Platinum CRPS Power Supply (GW-CRPS3000L5R)

3. Teardown of Belkin BoostCharge Pro Dual USB-C 67W GaN Wall Charger (WCH020yz)