Introduction

Stepping out of one's comfort zone has never been easy, even for tech giants like Apple. However, with the "help" of the European Union, Apple has finally replaced the outdated Lightning port on the iPhone with the more versatile and higher-performance USB-C port, bringing us one step closer to the dream of "one cable rules them all."

Today, ChargerLAB has got Apple's latest release, the 240W USB-C Charge Cable. With this cable, you can effortlessly charge your iPhone 15 series at speeds of up to 30W and power up your MacBook Pro at 100W. But how does it fare in terms of build quality? Let's take a closer look.

Product Appearance

The packaging box still adopts Apple's classic style,

with product names in multiple languages on the back.

Model is A2794.

While it can support power transmission of 240W, the data transmission is limited to USB 2.0 speeds.

Inside the package, you'll find only the cable itself and a few documents.

The cable features a woven design that would make it an excellent choice as the standard charging cable for the MacBook series.

There is no protect sleeve between the connector and the cable, as Apple appears to rely on the woven design for protection.

The model is also located on this connector, along with the place of production - Vietnam.

And the 240W is on the other side.

It adopts a non full-pin design, which is reasonable for a USB 2 cable.

The cable feels solid to the touch while remaining relatively flexible.

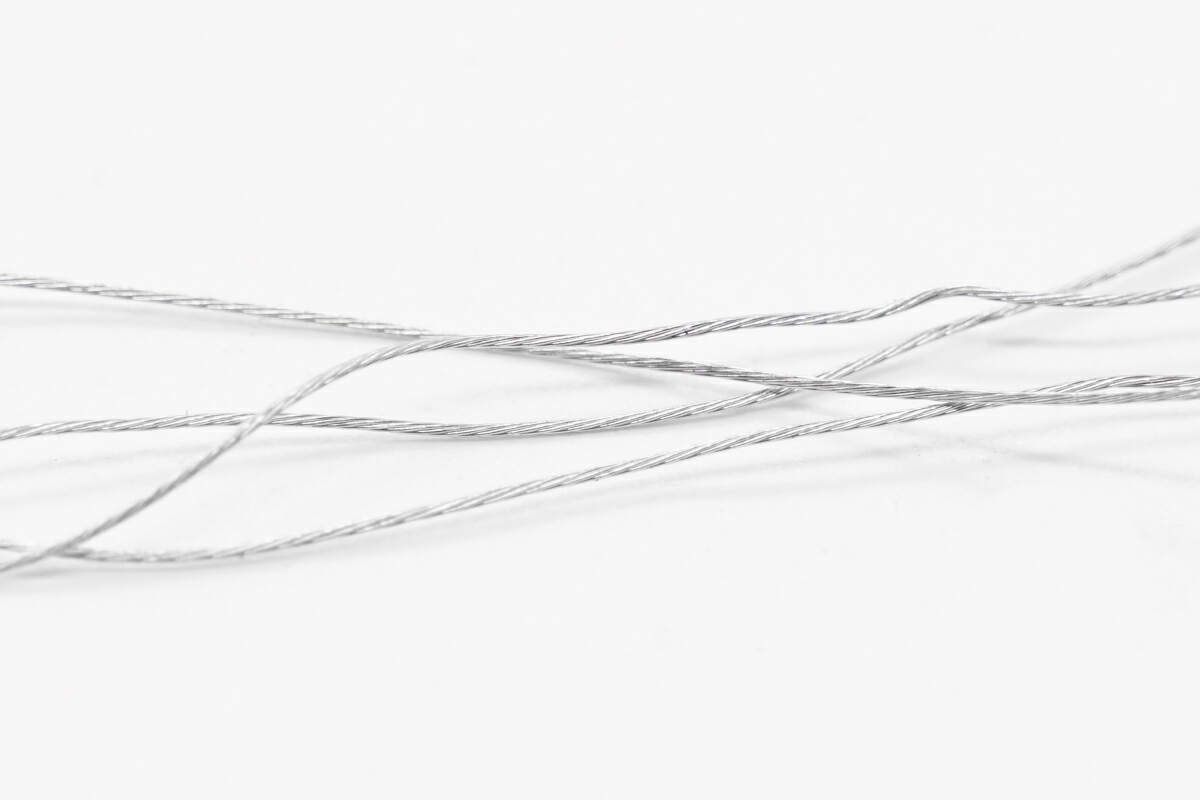

The woven outer layer twists the fibers into strands before arranging and weaving them together, preventing tangling and enhancing durability.

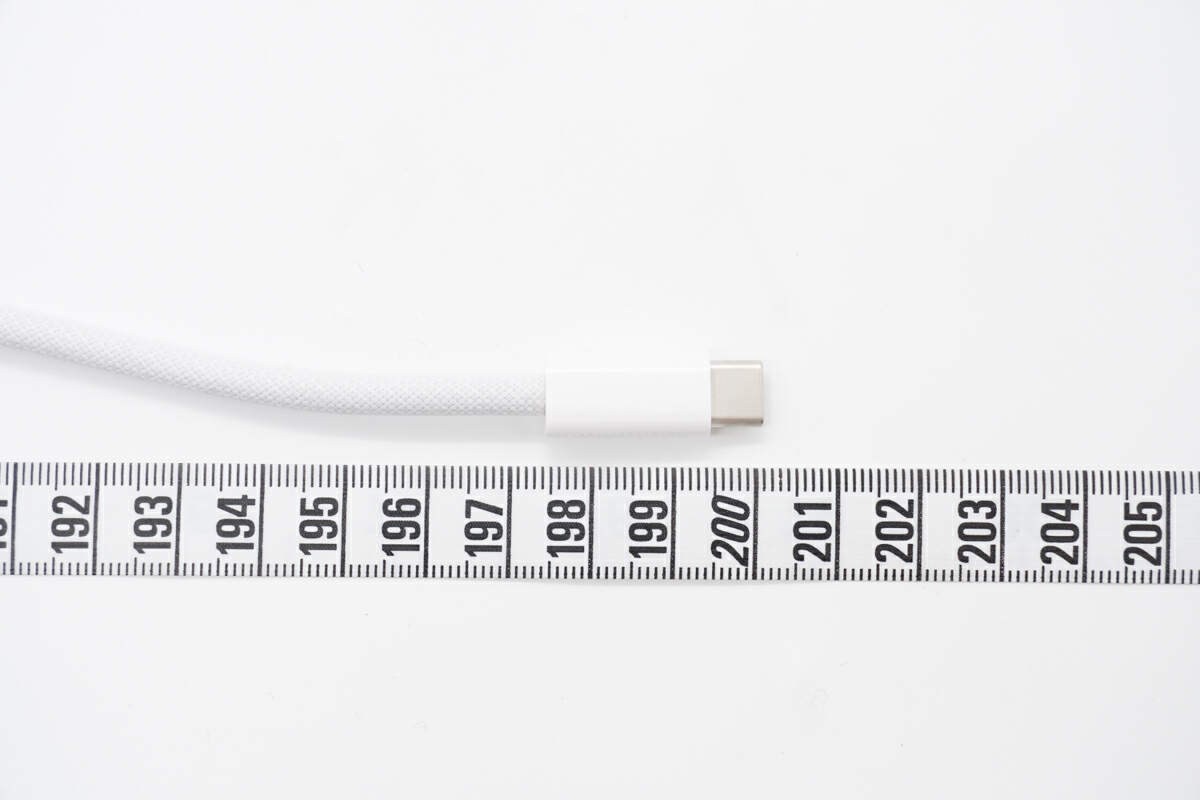

The cable length is exactly 2m (6' 6.72'').

And the diameter is about 4.6mm (0.18 inches), which is pretty thick.

The overall weight is about 78g (2.75 oz).

This is how it looks like on my hand, the thickness is more obvious.

Our ChargerLAB POWER-Z KM003C indicates that it is a USB 2 cable capable of power transmission at 50V5A 240W, aligning with its advertised specifications. Furthermore, it comes with an E-marker chip.

Test

Before diving into the teardown, let's conduct a few simple tests, including charging and data transfer.

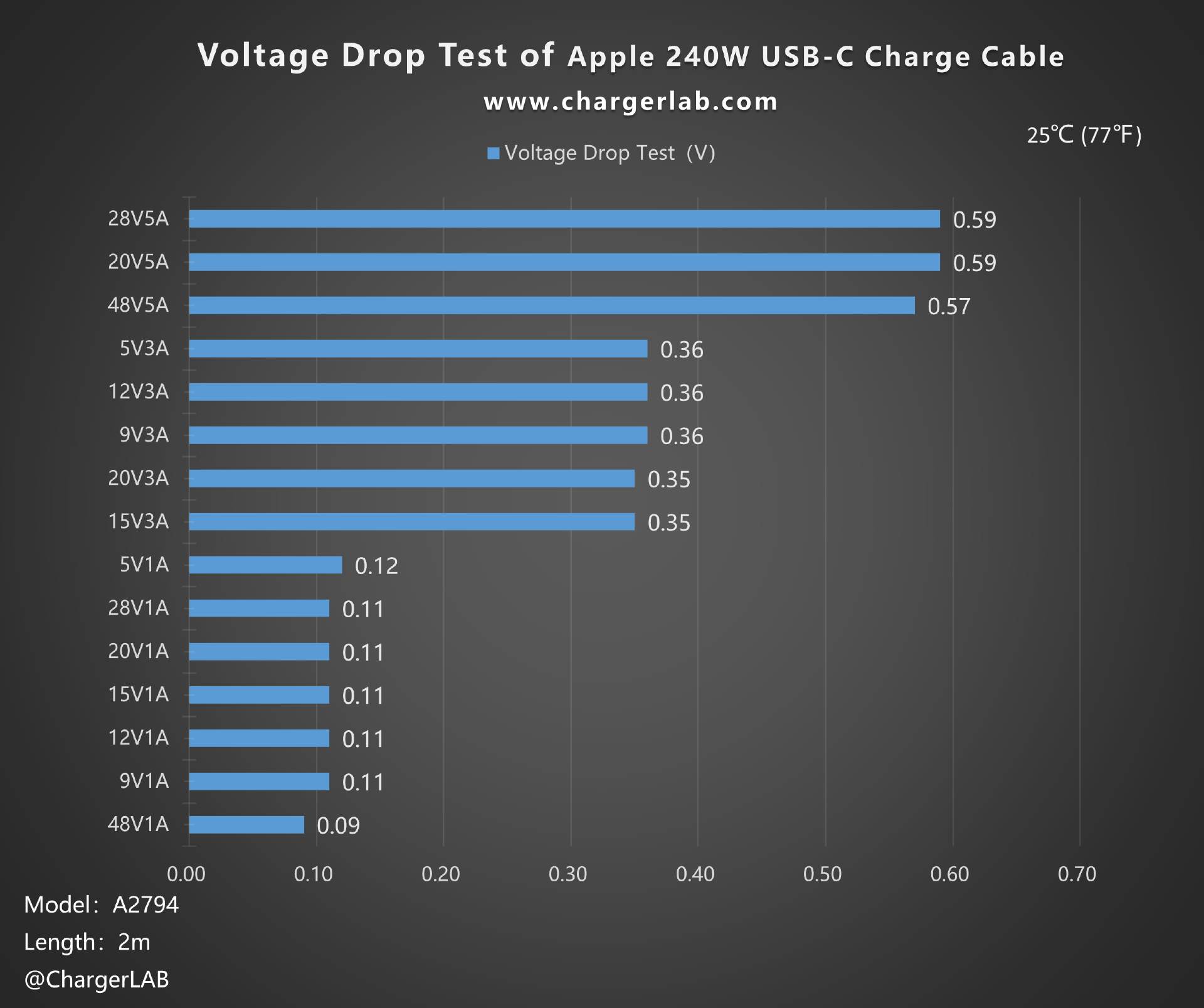

Firstly, we performed a voltage drop test using the brand-new ChargerLAB P240 Bidirectional Multi-protocol Power Supply, which has not yet been released.

This test measured the difference of the input and output voltages, which represents the voltage drop. The results are shown in the bar chart, providing an easy-to-understand visualization.

From the chart, we can see that the voltage drop falls into three categories: 0.11, 0.25, and 0.58. In the context of USB-C cables, this performance level is considered normal.

Currently, there are no devices on the market that support 240W PD fast charging. So, we use this cable to charge the Apple MacBook Pro. The measured charging power was approximately 92W.

Taking it a step further, we used an Apple 140W charger to juice up a power bank that supports 140W PD input. The power can be be to 133W.

Lastly, we connected this very cable to a laptop and an SSD enclosure. The system recognized the SSD, confirming the cable's support for data transmission.

Using the Disk Speed Test to assess transfer speeds, the measured write speed was approximately 32.9MB/s, while the read speed was around 35.8MB/s, in accordance with the USB 2.0 data transmission standard.

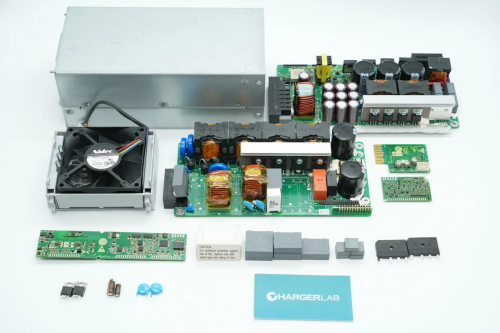

Teardown

After reviewing this cable, let's take a closer look at its internal components and build quality.

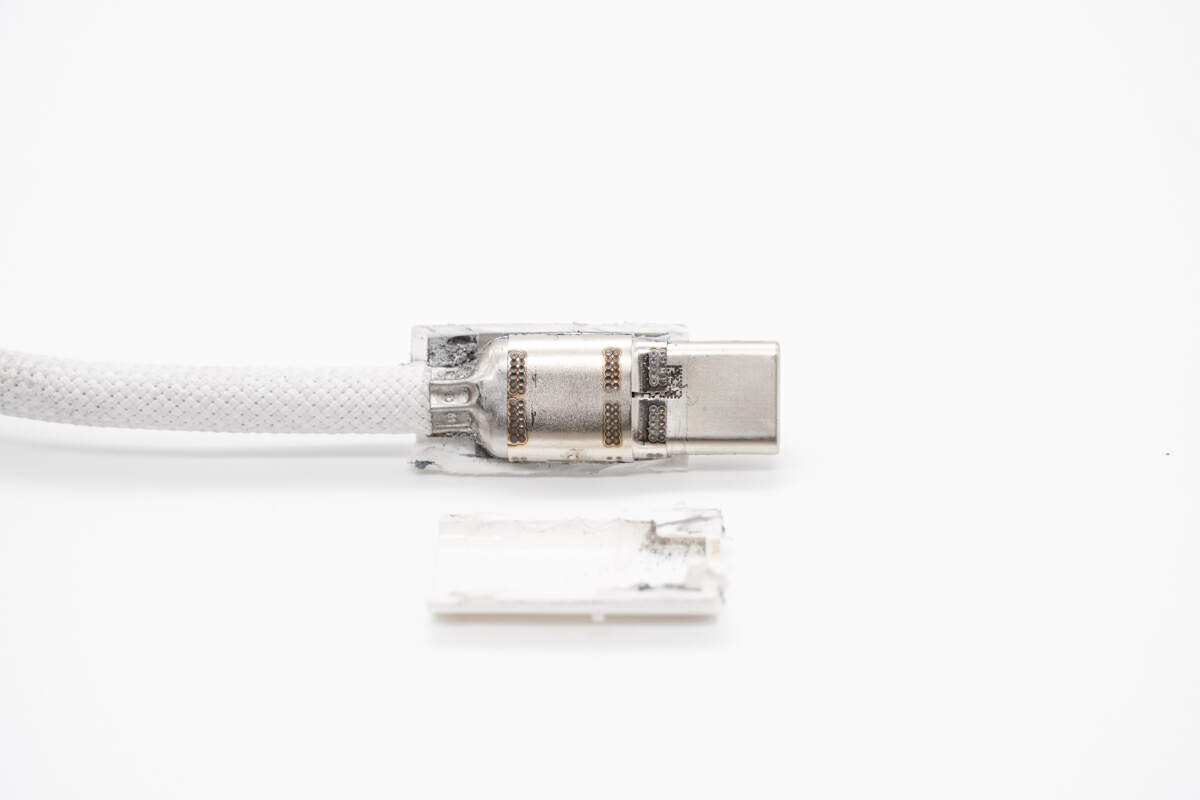

Firstly, let's use the cutting machine to cut off the USB-C connector. Just like all Apple cables in our pervious teardown articles, it has a steel sleeve to protect internal components, which is fixed by plenty of solder joints.

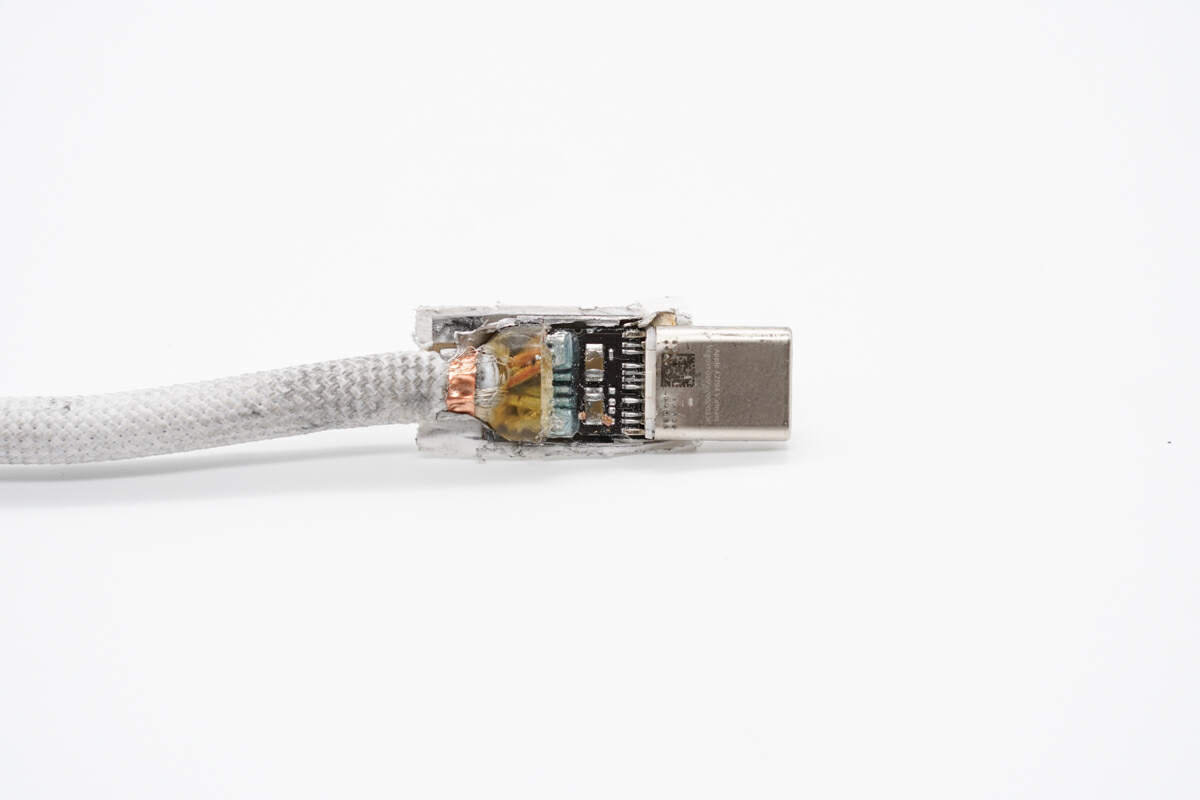

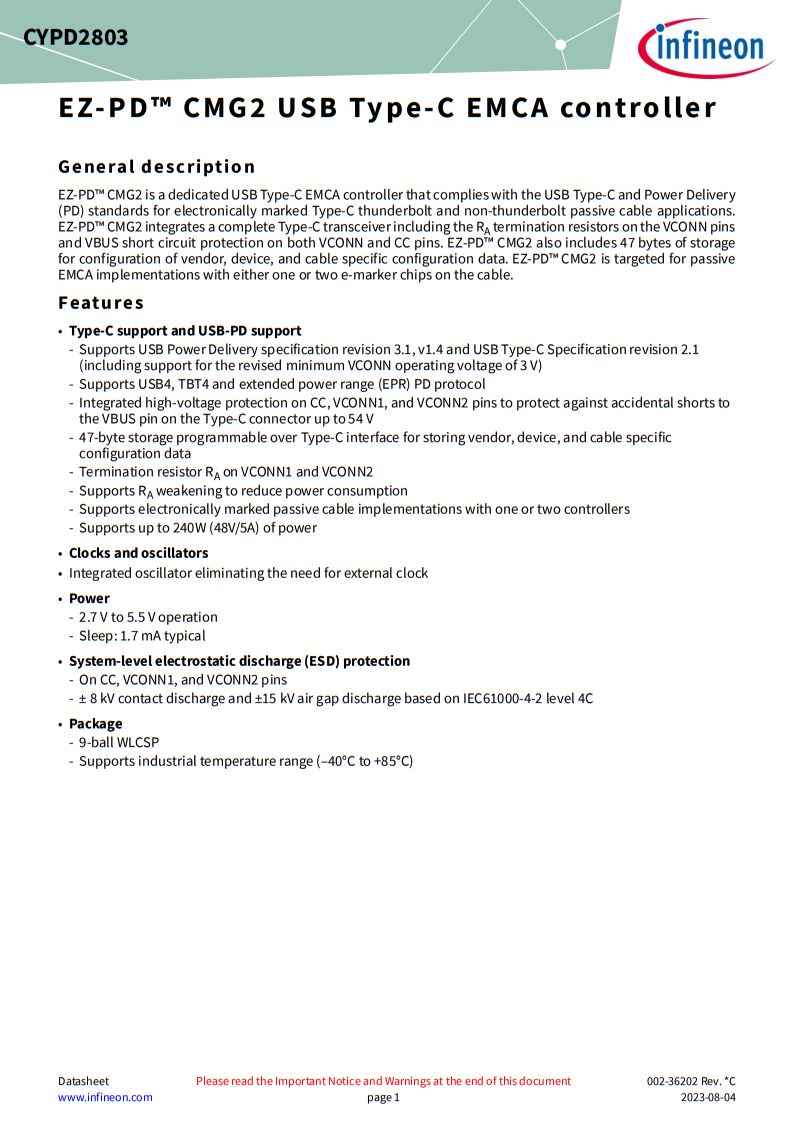

Continuing to remove the steel sleeve, the PCB is black, just like most Apple products.

From left to right, you can see the three-in-one positive wire, CC wire, USB 2.0 data wire, and bare wire.

At the top, there are two SMD capacitors.

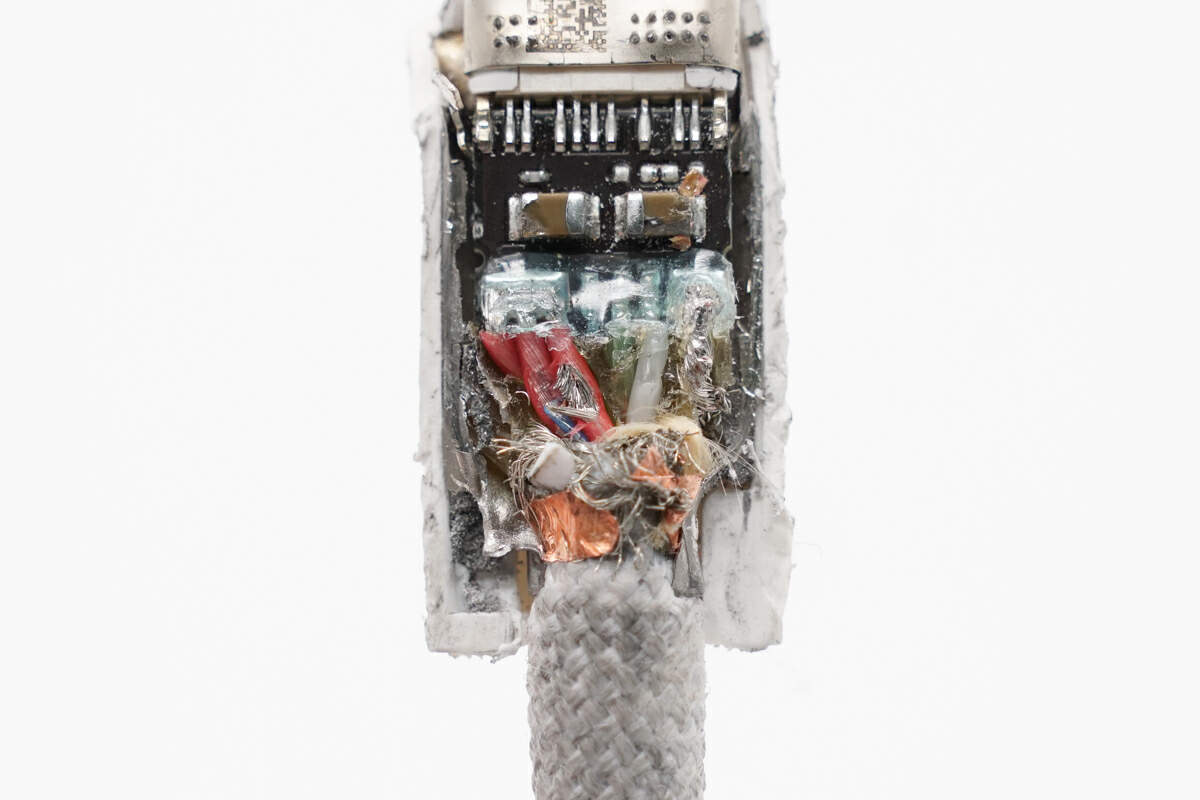

Removing the remaining steel sleeve from the back, a significant amount of potting compound can be observed in the center.

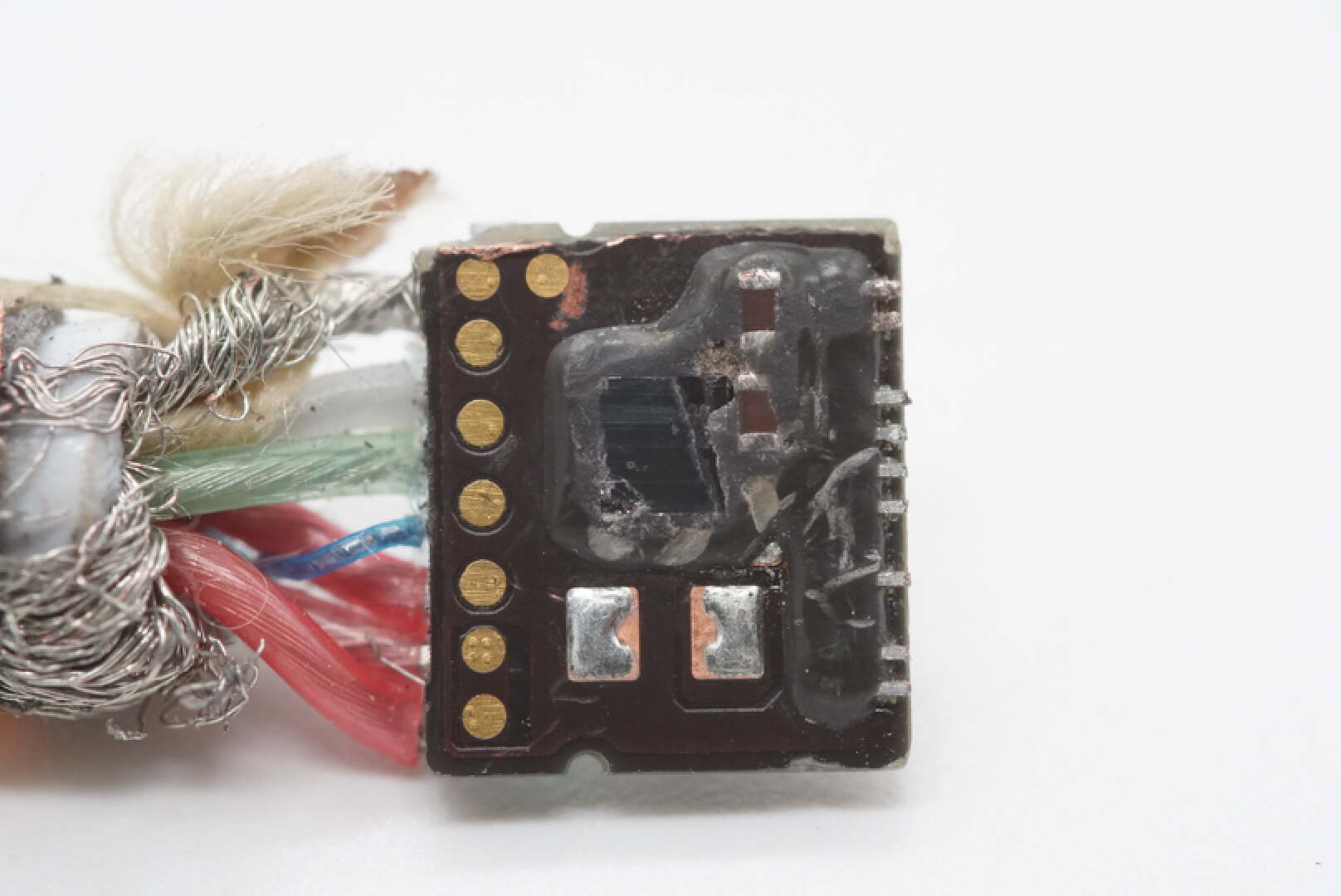

During the process of cleaning the potting compoundc, we accidentally scraped off the markings on the chip. And this is, in fact, an E-marker chip manufactured by Infineon, specifically the CYPD2803 model. It complies with the USB-C and PD standards and is intended for electronically marked Type-C cables, both for thunderbolt and non-thunderbolt applications

It integrates high-voltage protection to safeguard against accidental shorts to the VBUS pin on the Type-C connector, offering protection up to 54V. It also provides full support for PD 3.1 and USB4. So, the fact that its data transfer is limited to USB 2 is pretty sad.

The other connector have the exact same layout, so we just show you the other E-marker chip.

Next, remove the metal shell of the USB-C connector, and you'll find that the internal pins are secured using a plastic bracket.

The non-full pin design of the gold-plated pins becomes more evident.

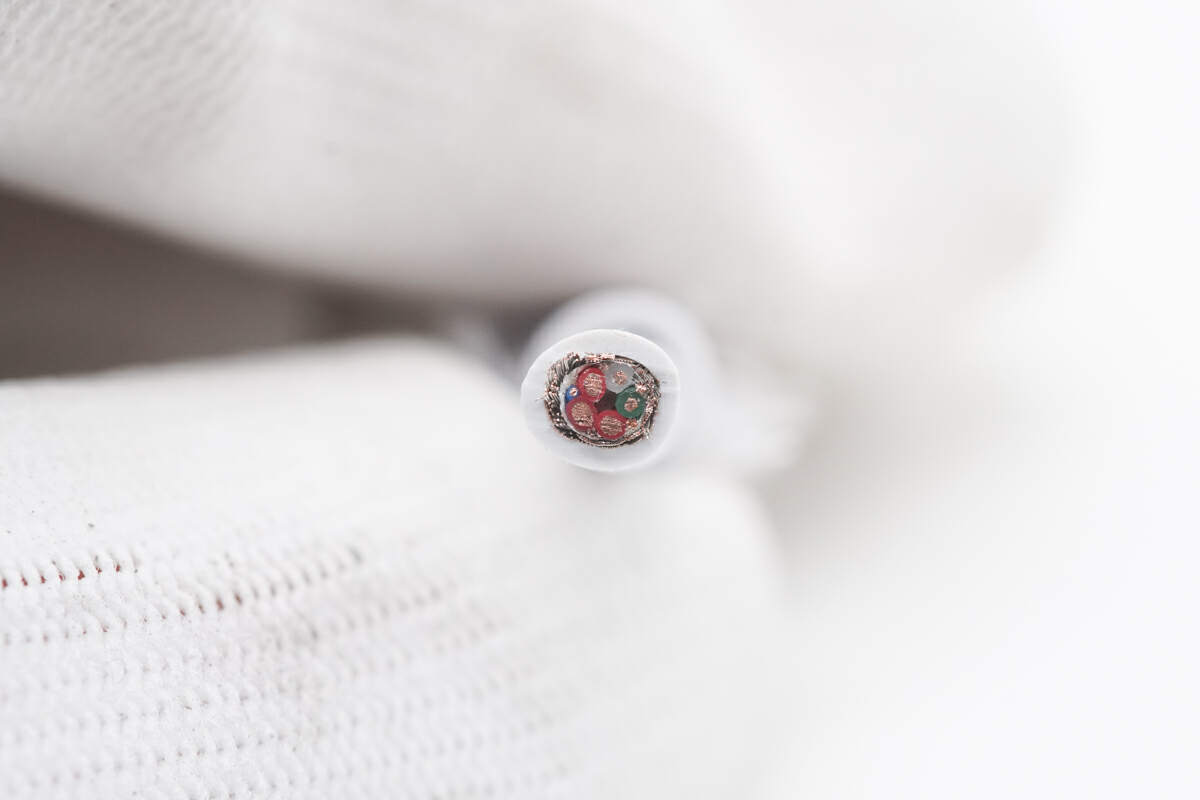

Then, cut off the cable. The twisted structure on the woven layer causes it to gather together even when cut off.

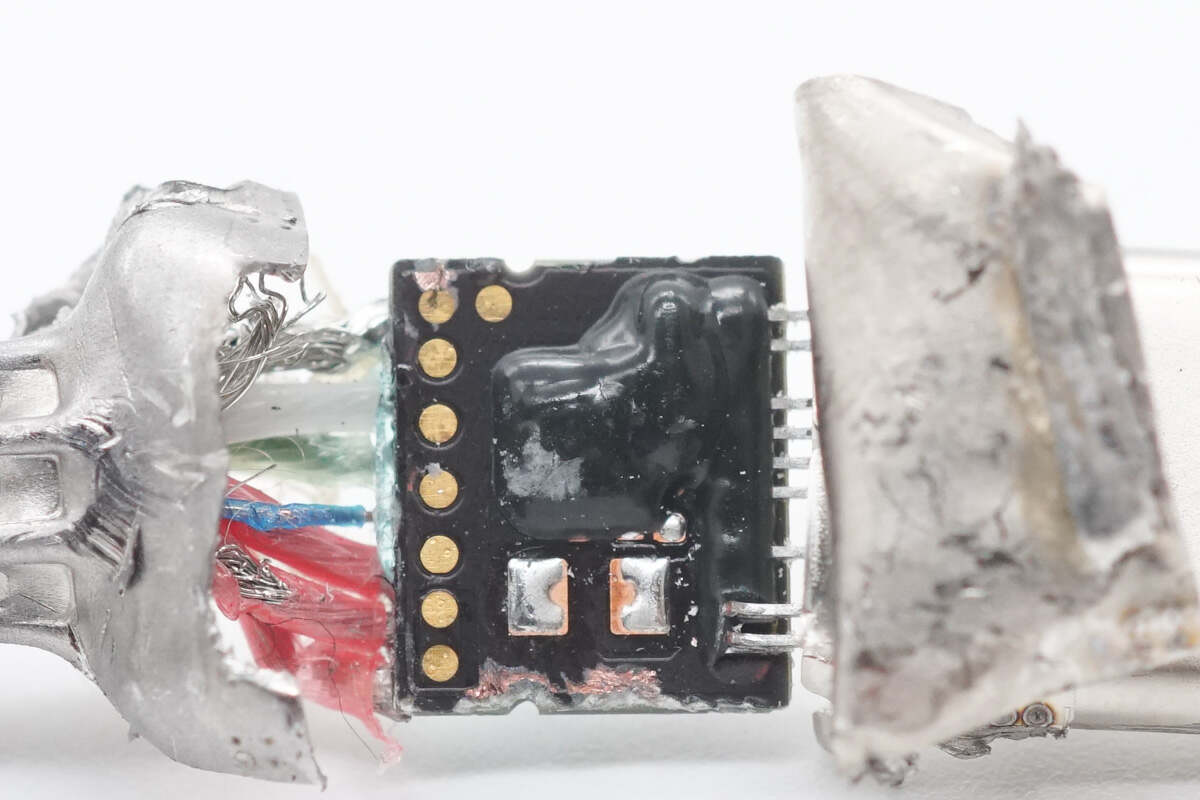

Just like we talked about before, there are a total of six wires inside. Three of them are colored red and serve as positive power supply wires, and that's why they have a thicker core. Meanwhile, the white and green wires next to each other are USB 2.0 wires. The thin blue wire on the edge represents the CC wire, while the bare wire cores surrounding it function as negative pole wires.

Inside the woven layer, you'll find white TPE.

And there's a layer of shielding net under it.

The final layer of protection consists of aluminum foil.

Some tensile fiber is under the aluminum foil to improve its durability.

Here is a close-up of the cable's internal structure, including the outer woven layer, white TPE, shielding net, aluminum foil, power wire and data wire, as well as tensile fibers. Now let's take a more detailed look at the wire design inside the cable.

The core inside the positive power supply wire is made of tinned copper, and there are no tensile fibers.

The blue CC wire adopts a unique rotating and winding structure.

This is the green D+ wire.

And the white one is the D- wire, they're used for USB 2.0 data transmission.

These four bare tinned copper wires are connected in parallel, and used for negative power supply.

This is the tensile fibers we talked about before.

Well, that would be all components of this cable.

Summary of ChargerLAB

In summary, this Apple 240W USB-C Charge Cable, supported by the E-marker chip, offers PD 3.1 fast charging capabilities with a maximum charging power of 240W. It's ideal for fast-charging electronic products, including the MacBook Pro, that support PD fast charging. However, its data transfer is limited to USB 2 for some reason, which means it can not fully utilize the potential of the latest iPhone 15 Pro and Pro Max models, users with these models are advised to consider the Apple Thunderbolt4/USB4 Pro Cable.

Additionally, its unique woven layer design and tensile fibers significantly enhance its durability, coupled with multiple shielding layers, meeting Apple's high-quality build standards.

Related Articles:

1. Limited to USB2.0? | Teardown of Apple 240W USB-C Charge Cable (Video)

2. Teardown of Apple C91M Lightning to USB-C Cable

3. Quick & Easy | Latest Teardown of Apple USB-C to MagSafe 3 Cable (2 m)